TPO Waterproof Sheet Extrusion Line

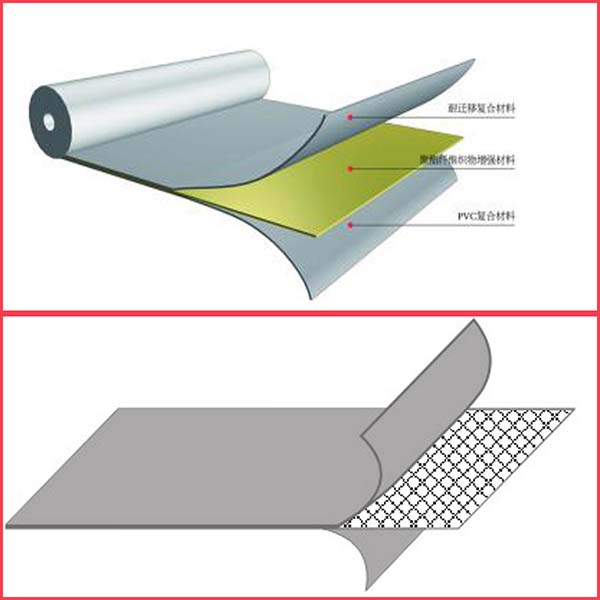

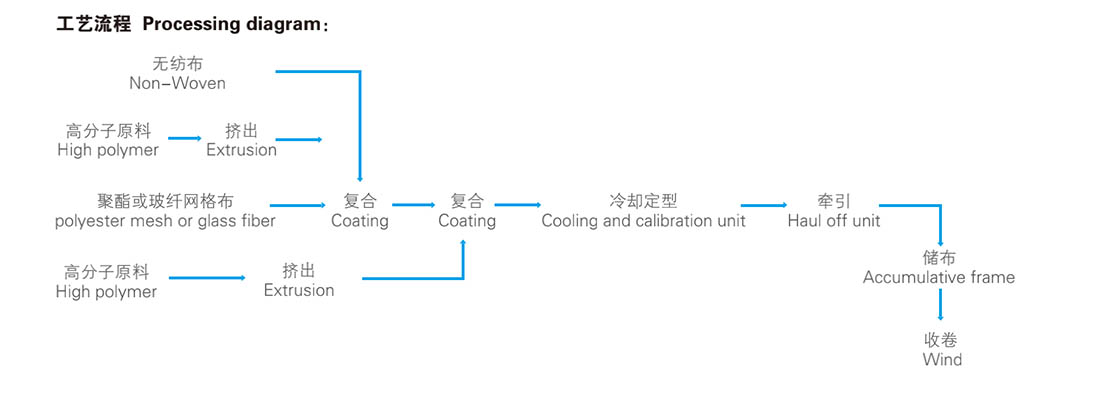

Jwell company adopts the solid roll for combining multilayers, this new technology make the TPO sheet having a good function against wind uncovering.TPO waterproof sheet is a new type of waterproof product, which is produced with thermoplastic polyole-fin plus antioxygen and plastifier and so on, the middle layer is polyester fabric for reinforcement, the surface is laminated with textile fiber and aluminum foil. This kind of TPO waterproof sheet has the features of good weatherproof and suppleness. It is mainly used for house, tunnel, basement architecture and other waterproof fields.

Used for different kinds of plastic material, such as PVC, TPO,etc.Being able to produce below sheets:

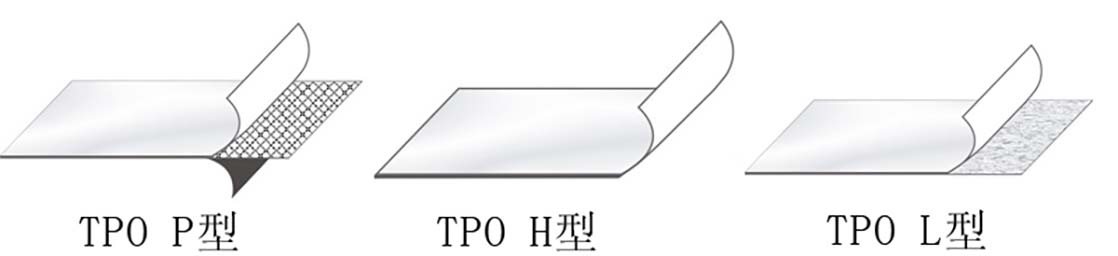

Plastic roll sheet (model: H): without coating with inner reinforced material or outer material.

Roll sheet with outer fiber (Model: L): coating with fiber or non-woven fabric.

Inner reinforced roll sheet (Model: P): Inner layer coats with polyester mesh.

Inner reinforced roll sheet (Model: G): Inner layer coats with glass fiber.

Features of TPO waterproof coiled material

1. Ethylene propylene rubber and polypropylene are combined by advanced polymerization technology, which has both excellent weather resistance of ethylene propylene rubber and weldability of polypropylene.

2. The special formulation technology does not need to add any plasticizer that is easy to make the material brittle, does not produce the embrittlement of general hot welded coiled materials (such as PVC) due to the migration of plasticizer, and maintains the long-term waterproof function.

3. Excellent high and low temperature resistance. Like rubber materials, it still maintains flexibility at - 50 ℃ and mechanical strength at higher temperature.

4. Chemical resistance, acid, alkali, salt, animal oil, vegetable oil, lubricating oil corrosion, algae, mold and other microbial growth.

5. It has excellent root puncture resistance and can be used as root puncture resistant coiled material for planting roof.

6. Heat aging resistance and good dimensional stability.

7. The light colored surface dominated by white has smooth surface and high reflectivity, which has energy-saving effect

8. The lap joint is constructed by thermal welding, which can form a high-strength and reliable sealing waterproof layer.

9. The reinforced TPO waterproof coiled material is sandwiched with a layer of polyester fiber fabric in the middle, which provides the coiled material with high tensile performance, high tear strength, fatigue resistance and puncture resistance, and is more suitable for mechanically fixing the roof system.

10. The backing TPO waterproof coiled material is the fabric on the lower surface of the coiled material, which makes the coiled material easier to bond with the base layer.

11. Homogeneous TPO waterproof coiled material has good plasticity and can be processed into various shapes after heating to adapt to the practice of complex nodes

Main technical specification

|

Model |

SJP130/36-SJZ92/188-3400 |

JWP130/26+JWP130/26-2400 |

|

Product structure |

TPO+(Net)+TPO |

PVC+(Net)+PVC |

|

Products width |

3200mm |

2200mm |

|

Products thickness |

0.8-3mm |

0.5-3mm |

|

Extruder model |

SJP130/36-SJZ92/188 |

JWP130/26+JWP130/26 |

|

Capacity |

1200kg/h |

1500kg/h |

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.