High Molecular Weight(Hmw) Plastic Reinforced Steel Bridge Extrusion Machine

Characteristics

HMW Plastic Reinforced Steel Bridge mainly divide into composite plastic bridge and plastic reinforced steel bridge. It is a kind of new and advanced bridge material series product. It already has been widely used in chemical industry, petroleum, electric power, medicine, construction and other industries and coastal areas. It can replace current traditional cable tray, and has been widely used in developed countries in EU and USA. It is the preferred cable tray for future engineering application. It conforms to the national policy of "replacing steel with plastic", and has the characteristics: flame retardant, corrosion resistance, excellent mechanical strength, good insulation performance, suitable structure, beautiful appearance and long service life. It integrates steel bridge, glass fiber reinforced plastic bridge and aluminum alloy bridge in different conditions and climatic conditions.then researched and developed.

Polymer cable tray has the following characteristics

1. Polymer cable tray is made of high-tech polymer material PVC and ABS polyphenylene oxide. It has the advantages of strong heat resistance, low coefficient of thermal expansion, good flame retardancy, high insulation performance, strong corrosion resistance and long service life. It has great advantages over traditional products.

2. The structural optimization design improves the flexibility and quickness of cable tray installation. The traditional cable tray structure is complex and requires many parts, while the new alloy plastic cable tray can greatly meet the needs of customers by using only dozens of parts, which greatly improves the flexibility and quickness of cable tray installation.

3. Improve the utilization rate of polymer materials, which is about 5% higher than the conventional through verification. Polyphenylene oxide has outstanding mechanical properties, especially good tensile strength, impact strength, corrosion resistance and creep resistance. Under 21MPa load for 3000h, the creep value is only 0. 75%, while PC is 1% and POM is 2. 3%, ABS 3%. By fully mixing with PVC, the utilization rate is improved, which is more than 5% higher than that of conventional.

4. The product has good appearance design and high decoration. The product is made of plastic materials with strong plasticity and processed by injection molding and extrusion molding. It has good appearance design. Through structural optimization design, it can be combined arbitrarily and has strong decoration. It overcomes the shortcomings of poor appearance and low decoration performance of traditional products.

5. The service life of polymer bridge is very long. Compared with the traditional steel bridge, the service life is 5-8 times longer, reducing the secondary investment cost of replacing the bridge. The traditional steel bridge products have poor anti-corrosion performance, so the bridge must be painted and repaired regularly. The material cost and labor cost are high, while the polymer bridge has strong corrosion resistance, which greatly reduces the maintenance cost and maintenance time. The alloy plastic cable tray does not need to be powered off during maintenance, and the loss caused by production shutdown is reduced accordingly, which effectively improves the production efficiency.

Main technical specification

|

Model |

SJZ65&JWS45 |

SJZ80&JWS50 |

SJZ92&JWS50 |

|

Screw(mm) |

65/132 |

80/156 |

92/188 |

|

Output(kg/h) |

150-200 |

250-350 |

500-600 |

|

Motor power(kw) |

37 |

55 |

110 |

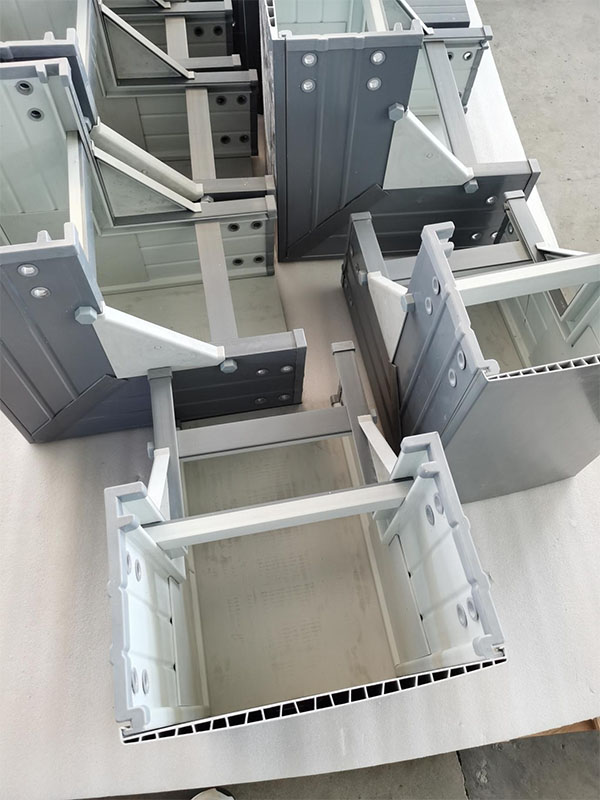

Product image display

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.