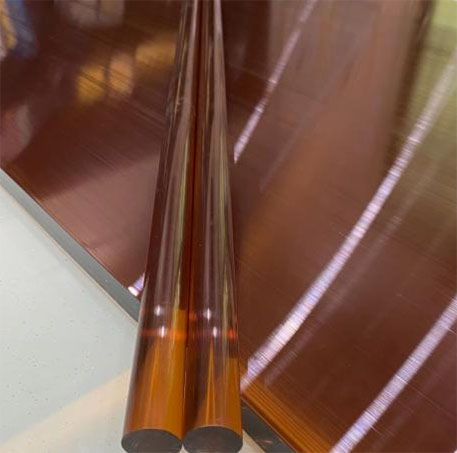

PEEK/PPS/PPSU/PEI/POM/PA Cold Push Bar and Sheet Production Line

PPS plastic (polyphenylene sulfide) is a kind of thermoplastic special engineering plastic with excellent comprehensive performance.The main use of PPS is in the field of electronic appliances, such as making transformer skeletons, high-frequency coil bobbins, plugs, sockets, wiring frames, contactor drum drums and various precision parts.

PEI has good flame retardancy, chemical reaction resistance and electrical insulation characteristics. Pei also has low shrinkage and good isotropic mechanical properties. Adding glass fiber, carbon fiber or other fillers can achieve the purpose of reinforcement and modification; It can also form heat-resistant polymer alloy with other engineering plastics, and can be used for a long time at the working temperature of - 160 ~ 180 ℃.

Application: because PEI has excellent comprehensive balance performance, it is generally used in industrial departments such as electronics, motor and aviation, and as a metal substitute for traditional products and cultural and daily necessities. Using PEI instead of metal to manufacture optical fiber connector can optimize the component structure, simplify its manufacturing and assembly steps, and maintain more accurate dimensions. It is used in the automotive field, such as manufacturing high-temperature connectors, high-power lamps and indicator lamps, sensors for controlling the external temperature of automobile compartments (air conditioning temperature sensors) and sensors for controlling the temperature of air and fuel mixtures (effective combustion temperature sensors). It can also be used as vacuum pump impeller resistant to high temperature lubricating oil erosion, ground glass joint (socket) of distiller operated at 180 ℃, and reflector of non illuminated anti fog lamp.

POM plate and bar

(1) POM is a crystalline plastic with good rigidity, commonly known as saigang.

(2) It has excellent properties such as fatigue resistance, creep resistance, wear resistance, heat resistance and impact resistance.

(3) POM is not easy to absorb moisture and has good dimensional stability in humid environment. It is difficult to control the size during injection molding. The thermal deformation temperature is 172 ℃, and there are two kinds of polyoxymethylene with different properties (polyoxymethylene has better temperature resistance).

Main technical specification

|

Model |

SJZ45/25, SJZ65/28 |

|

Material |

PEEK/PPS/PPSU/PEI/POM/PA |

|

Main engine rate of revolution |

10-49r/min |

|

Main motor power |

11KW |

|

Capacity |

20kg/h |

Note: The specifications are subject to change without prior notice.

Plant equipment diagram

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.