Automobile Material Extrusion Machine

-

EVA/POE/TPO Automotive Soundproof Sheet Extrusion line

Car Sound Insultation Pad(Vibration Damping Pad) is made of EVA, TPO, PVC and high filling inorganic. It is placed directly on the metal part, which eliminates the noise from the source and avoid the noise transmission in the metal.

-

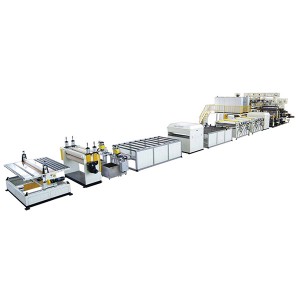

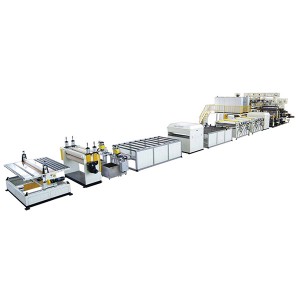

HDPE Thermoforming Plate Extrusion line

Jwell supply advanced extrusion system, it is suitable to produce HMW-HDPE material which have low MFI and high-strength into plate, the plates are mainly used to produce auto carriage board, pick-up’s box liner, cover of truck, anti-rain cover etc.

-

LFT/FRP Continuous Fiber Reinforced Composite Extrusion Line

Continuous fiber reinforced composite material is made of reinforced fiber material: glass fiber(GF), carbon fiber(CF), aramid fiber(AF), ultra high molecular polyethylene fiber(UHMW-PE), basalt fiber(BF) by using special process technology to makes high strength continuous fiber and thermal plastic&thermosetting resin soak with each other.

-

PP Honeycomb Board Extrusion Line

Used for car trunk cover board, trunk clapboard, trunk carpet substrate, side wall decortation board, ceiling etc. interior place.

Used for manufacturing different kinds of high strength packing box.

-

TPE/TPO/PVC Flooring Footmat Extrusion line

Mainly used for producing the sort of PVC Floor leather rolls. PVC Floor leather has the performance of anti-friction, corrosion resistence, skidproof, impermeable and inflaming retarding, and is widely used on auto, hotel, amusement place, exhibition hall, house, etc.

-

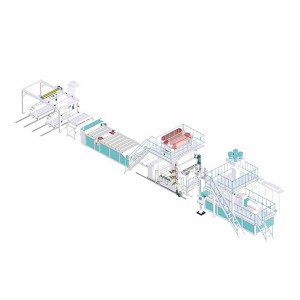

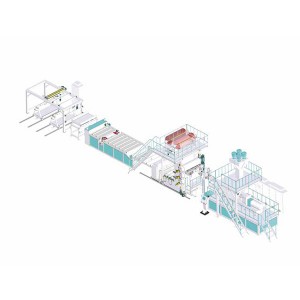

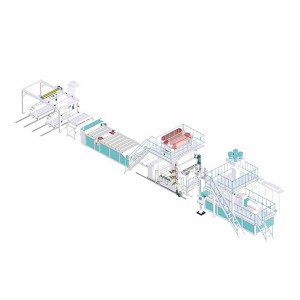

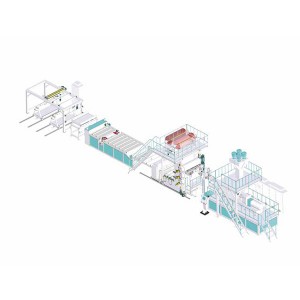

TPO/PVC+PP foam automobile interior skin composite embossing production line

Automobile interior skin composite materials are used in the interior of mid-to-high-end automobile instrument panel skins, automobile side door panels, seats and other interiors. This production line can realize online composite embossing and one-time shaping. It has advantages of high production efficiency, firm composite bonding, and convenient pattern modification.

-

TPO/TPU Composite Leather Extrusion Line

Polyolefin thermoplastic elastomer(TPO) composit leather roll (coating roll) has the advantages of enviroment friendly and abrasion and heat resistance. It has been used widely in the field of car inner decoration, i.e. instrument board skin, inner decoration skin, in-car flooring, car rear tank flooring, foot pad material. Its regular thickness is 0.2-3mm with width 1000-2000mm.

-

TPO+PP Foam Composite Sheet Production Line

The main machine of a plastic extrusion machine is an extruder, which is composed of an extrusion system, a transmission system and a heating and cooling system.

-

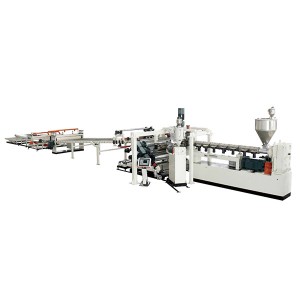

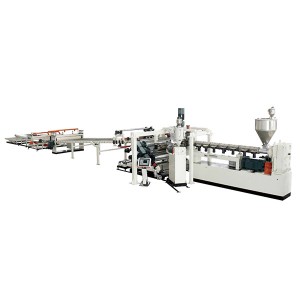

TPU/ABS Laminate Sheet Extrusion Line

TPU/ABS composit plate is one new kind of enviroment friendly material used for car gauge panel and inner decoration. It adopts multi manifold procee to make TPU coat on ABS instead of glue coating so that the finished product does not release formaldehyde or creat inner air pollution. Plate thickness from 1mm to 8mm, width from 1200mm to 2000mm.