Products

-

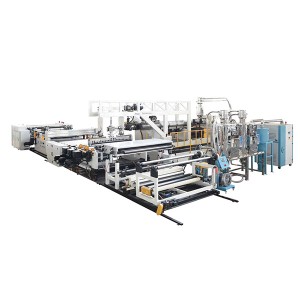

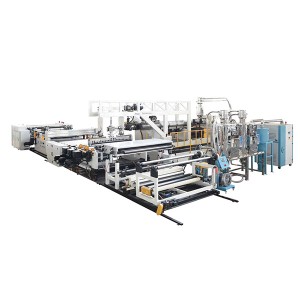

Single Layer Or Multi-Layer Coating Film Extrusion Line

Application range: Paper-plastic compound, Aluminum-plastic compound, Plastic-plastic compound, Paper-aluminum plastic compound.

-

UPVC/CPVC Pipe Extrusion Machine

A variety of specifications and models of PVC twin-screw extruder can produce pipes of different diameters and different wall thicknesses.

Specially designed screw structure with uniform plasticization and high output. Extrusion molds made of high quality alloy steel, internal flow channel chrome plating, polishing treatment, wear and corrosion resistance; with a dedicated high-speed sizing sleeve, pipe surface quality is good;

-

High Polymer Composite Waterproof Roll Extrusion Line

Used for different kinds of plastic material, such as PVC, TPO, PE etc.Being able to produce below sheets:

Plastic roll sheet (model: H): without coating with inner reinforced material or outer material.

Roll sheet with outer fiber (Model: L): coating with fiber or non-woven fabric.

Inner reinforced roll sheet (Model: P): Inner layer coats with polyester mesh.

Inner reinforced roll sheet (Model: G): Inner layer coats with glass fiber.

-

Horizontal HDPE Double-wall Corrugated Pipe extrusion machine

Jwell newly developed horizontal double-wall corrugated production line is a second-generation horizontal pressure water cooling production line, which is independently developed on the basis of domestic and international advanced technologies. It has more than ten invention patents.

-

TPO/PVC+PP foam automobile interior skin composite embossing production line

Automobile interior skin composite materials are used in the interior of mid-to-high-end automobile instrument panel skins, automobile side door panels, seats and other interiors. This production line can realize online composite embossing and one-time shaping. It has advantages of high production efficiency, firm composite bonding, and convenient pattern modification.

-

High Pressure RTP Twisted Composite Pipe Extrusion Machine

The thermoplastic reinforced pipe RTP has three layers: the inner layer is anti-erosion and wearing-resistant PE pipe;

-

PVC Imitation Marble Board Extrusion Line

The surface of the board is covered with imitation marble pattern, or heat transfer imitation marble pattern and UV curing treatment, good scratch resistance.

-

POE/EVA Solar Film Extrusion Machine

EVA/POE film is used in solar photo voltaic power station, building glass curtain wall, automobile glass, functional shed film, packaging film, hot melt adhesive and other industries.

-

TPU Film /Hot Melt Film Extrusion Machine

TPU material is thermoplastic polyurethane, which can be divided into polyester and polyether. TPU film has excellent characteristics of high tension, high elasticity, high wear resistance and aging resistance, and has the excellent characteristics of environmental protection, non-toxic, mildew proof and antibacterial, biocompatibility, etc.

-

DYSSG Pipe Crusher and Shredder Unit

DYSSG shredder is able to shred the PE, PP, PVC pipe with diameter 1200mm, the length of 3-6m pipe can be shredded directly without cutting, and the rotary speed is slow and stable. Variety of pipes is put into theflat feeding tank, and the tanks closed automatically, and push the pipe by hydraulic into the center axis for shredding.The material after crushing is transported by conveyor belt for secondary crushing in order to get the requested granule.