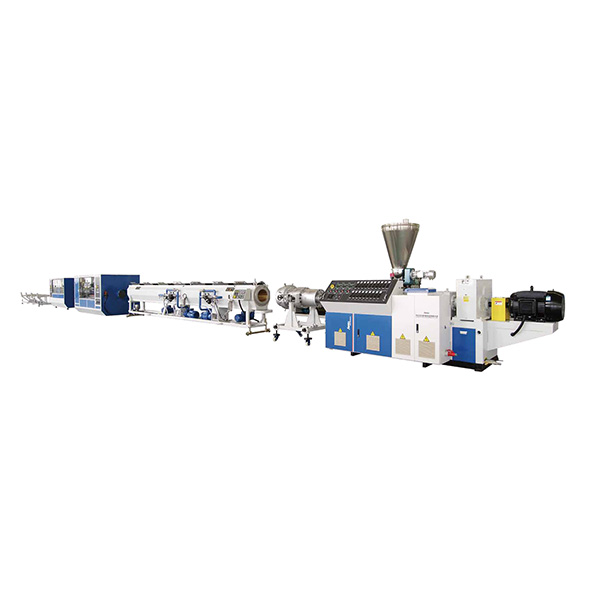

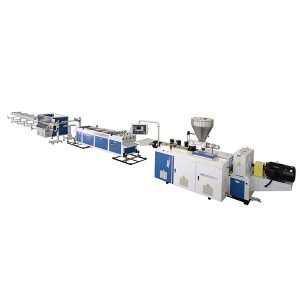

UPVC/CPVC Pipe Extrusion Machine

Performance&Advantages

A variety of specifications and models of PVC twin-screw extruder can produce pipes of different diameters and different wall thicknesses.

Specially designed screw structure with uniform plasticization and high output. Extrusion molds made of high quality alloy steel, internal flow channel chrome plating, polishing treatment, wear and corrosion resistance; with a dedicated high-speed sizing sleeve, pipe surface quality is good;

The special cutter for PVC pipe adopts a rotating clamping device, which does not require replacing the fixture with different pipe diameters. With chamfering device, cutting, chamfering, one-step molding. Support optional online belling machine.

PVC Pipe Die Head

It is for PVC 20-1000mm pipe production, split-flow frame design, very much suitable for temperature sensitive material. Adapting chrome plating mold steel, special surface hardness treatment, so that die head runner will have good flow. Easily disassembly design will offer quick change and will not affect production.

Vacuum Tank/Spray Cooling Tank Performance &Advantages

According to the specifications of the pipes can be selected single room or double room

design of the vacuum tank; SUS304 stainless steel vacuum tank and pipeline with long service life; Accurate temperature control and water level control;The large capacity of water filters and spare bypass;Centralized water supply and drainage;

Optional PLC frequency conversion precision control of vacuum degree, lower equipment energy consumption and noise;

The sizing sleeve made of high-quality materials such as alloy copper and stainless steel is particularly selected to ensure good heat conduction and a good cooling sizing effect. The inner surface of the sizing sleeve is treated with a chrome-plated special coating that provides high wear resistance and high smoothness. Water film type, disc type, dry type and other structural designs are suitable for high-speed, high-volume extrusion of different raw material pipes.

Main technical specification

|

Model |

Pipe diameter |

Extruder |

Main Power |

Capacity |

|

JWG-PVC160 |

Φ63-1600mm |

SJZ65/132 |

37kw |

250~300kg/h |

|

JWG-PVC250 |

Φ75-250mm |

SJZ65/132 |

37kw |

250~300kg/h |

|

JWG-PVC315 |

Φ160-315mm |

SJZ80/156 |

55kw |

300~400kg/h |

|

JWG-PVC450 |

Φ200-450mm |

SJZ80/156 |

75kw |

400~500kg/h |

|

JWG-PVC630 |

Φ315-630mm |

SJZ92/188 |

110kw |

650~750kg/h |

|

JWG-PVC800 |

Φ400-800mm |

SJZ92/188 |

132kw |

850~1000kg/h |

|

JWG-PVC1000 |

Φ500-1000mm |

SJZ110/220 |

160kw |

1100~1500kg/h |

Product image display

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.