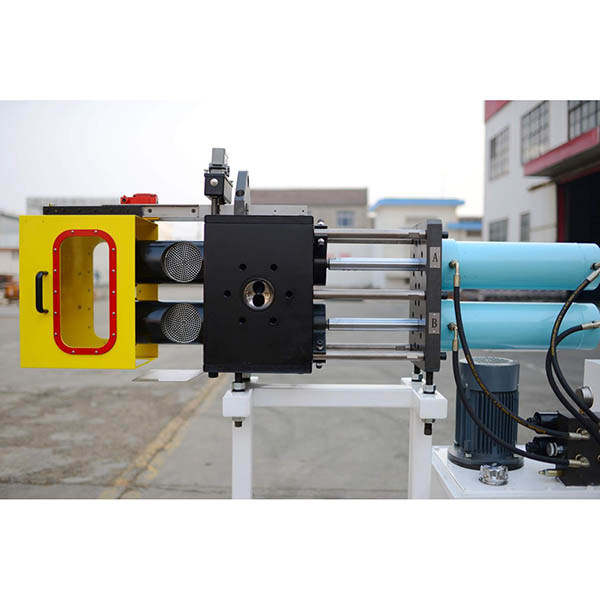

JW-SZ Double column with double working position hydraulic screen changer series

Double column with double working position hydraulic screen changer series

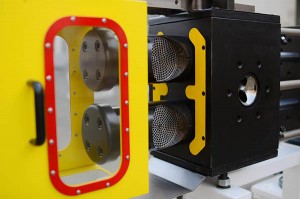

● No mechanical seal structure, which can guarantee the high pressure and high temperature condition not seep material. Effectively reduce the change screen resistance, reduce hydraulic system work pressure.

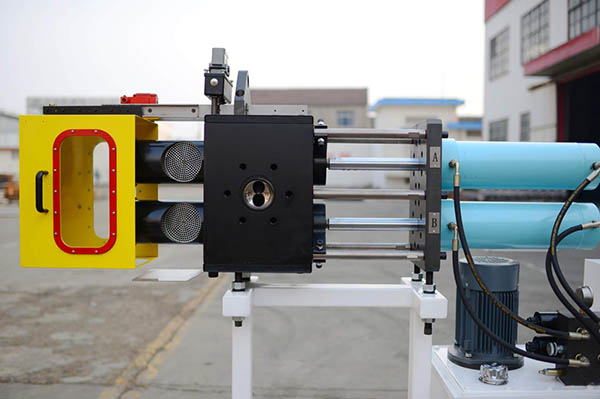

● Using High quality alloy steel, after nitriding process to extended product life span greatly.

● Integral engineering oil cylinder, a long use life.

● Alternating work mode, can guarantee the material flow continuous, stability and the process parameters of repeatability,when change the screen

● After optimization of rheological through cellular plate, to reduce the extrusion process fluid shear.

● Cooperate with stroke position sensor, change the screen more accurate, more controllable.

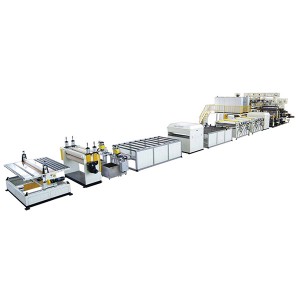

Suitable Application

Polymer with high liquidity, e.g. PET, PC, PMMA

Main technical specification

|

Model |

Filtration Area |

Output |

Operating pressure |

Heating Power |

Heating Zones |

|

JW-SZ-50 |

1960mm² ×2 |

50-150kg/h |

40Mpa |

7.5kw |

2 |

|

JW-SZ-70 |

3850mm² ×2 |

80-150kg/h |

40Mpa |

7.5kw |

2 |

|

JW-SZ-100 |

7850mm² ×2 |

150-350kg/h |

35Mpa |

9kw |

2 |

|

JW-SZ-120 |

11300mm² ×2 |

350-700kg/h |

30Mpa |

13.5kw |

2 |

|

JW-SZ-150 |

17670mm² ×2 |

400-1000kg/h |

28Mpa |

15kw |

2 |

|

JW-SZ-180 |

25440mm² ×2 |

700-1500kg/h |

20Mpa |

18kw |

2 |

Note: The specifications are subject to change without prior notice.

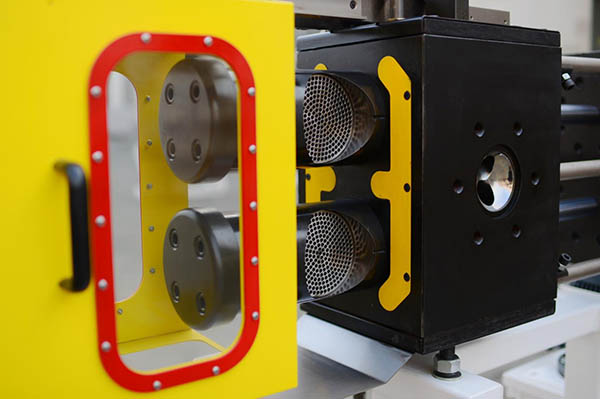

Product image display

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.