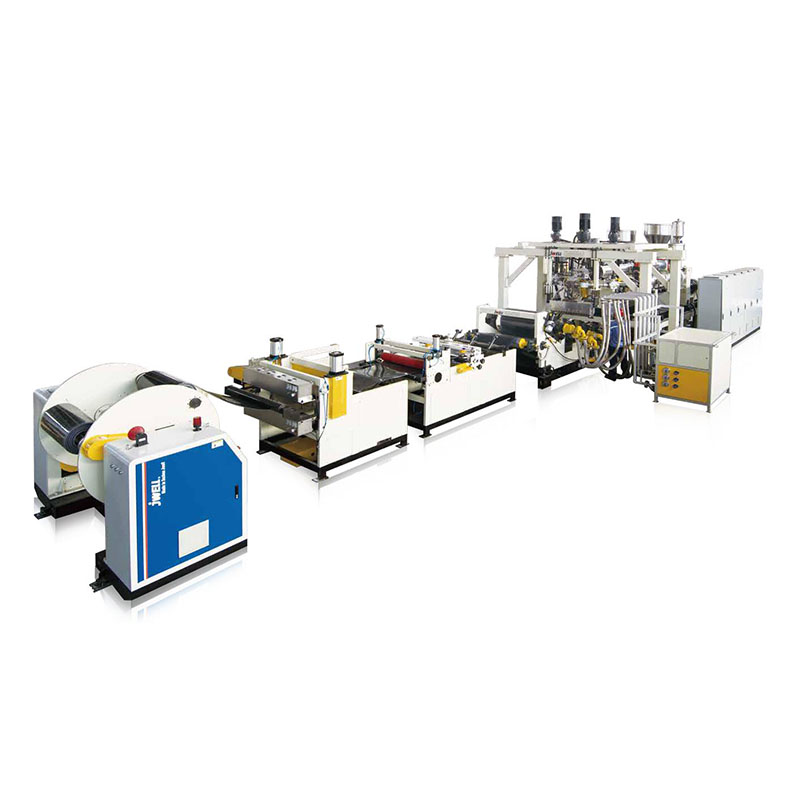

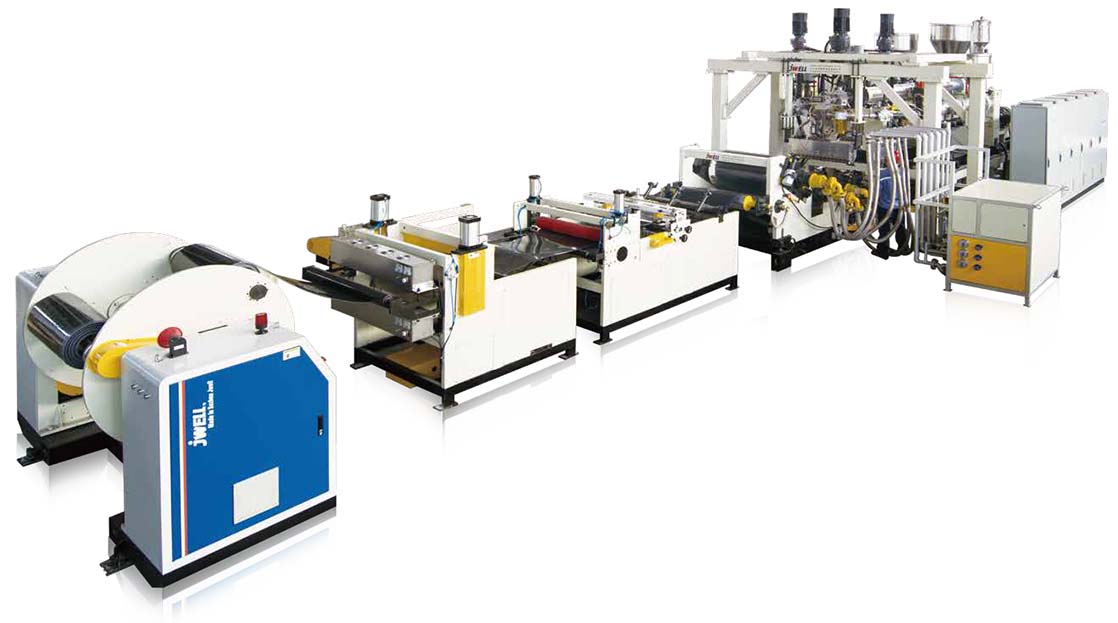

PP/PS thermoforming sheet, PP stationery sheet extrusion line

PP/PS sheet extrusion line is one kind of simple and standard machine among the sheet lines provided by JWELL,this line has the advantages of high capacity, good plasticization,easy operation and stable running.

PP/PS thermoforming sheet, PP stationery sheet

PP/PS single-layer,co-extrusion two-color,double-side transparent sheets are used in thermoforming and packing industry.PP transparent sheet, dull polish sheet (coarse and fine), two-color sheet and some other sheets are used in stationery industry.

PP / HIPS packaging sheet production line: PP and PS sheets are widely used, which can be directly used for the packaging of food and electronic products after Blister molding; With the higher sealing requirements of materials in the packaging industry, our company has launched a three-layer / five layer / seven layer co extrusion production line, which can meet the requirements of some customers. The output range is 100-1200kg / h, and you can make a variety of choices.

PP decorative sheet extrusion production line: plastic stationery sheet production line is suitable for PP and PE two-color sheets; PP glossy high transparent sheet; The production unit can be multi-layer coextrusion, equipped with metering and control system, which has the advantages of high yield, low consumption and reducing color difference.

PP micro foamed sheet has advantages. PP foamed sheet with density greater than 0.45g/m3 has good bending resilience and is not easy to deform, so it has a good application prospect in the field of folders; PP foam sheet with density of 0.6g/m3 has good mechanical properties; It has broad prospects in the field of automobile interior decoration, and can be processed into carpet support materials, backlight panels, sound insulation panels, luggage racks, interior decorations, covers, speakers, etc; PP foam sheet with density of 0.3g/m3 has good resilience and flexibility, which is suitable for packaging, partition board and other fields.

With the increasing domestic demand, thermoforming sheets of packaging plastics are used more and more widely, and the consumption is increasing year by year, with a promising prospect. In order to improve the shelf life of food, "sheet with high barrier performance" has become the goal of competitive development by various production enterprises.

Jwell has developed five layer symmetric and seven layer asymmetric distribution technology, which makes the products produced by the equipment obtain barrier performance. The composite high barrier fresh-keeping packaging sheet is mainly used in jelly packaging, meat food, fast food, rice and other food packaging, medicine, cosmetics and other packaging

Main technical specification

|

Model |

JW100-800 |

JW120-1000 |

JW130/60-1000 layer |

JW150/60-1200 |

JW150/120/90-1800 |

|

Products Width |

600mm |

800mm |

900mm |

1000mm |

1500mm |

|

Products thickness |

0.2-1.5mm |

0.2-2mm |

0.2-2mm |

0.2-2mm |

0.3-2mm |

|

Designed speed |

20m/min |

25m/min |

30m/min |

40m/min |

60m/min |

|

Capacity |

200-250kg/h |

350-400kg/h |

500-600kg/h |

800kg/h |

800-1000kg/h |

Note: The specifications are subject to change without prior notice.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.