WPC (PE&PP) Wood-Plastic Floor Extrusion Line

Description

Wood plastic composite board is a high-tech green environmental protection material mainly made of wood (wood cellulose and plant cellulose) as basic materials, thermoplastic polymer materials (plastics) and processing additives, which is evenly mixed and then heated and extruded by mold equipment. It has the properties and characteristics of wood and plastics. It is a new environmental protection high-tech material that can replace wood and plastics, Wood plastic composites is abbreviated as WPC. Wood plastic floor is made of wood plastic composite materials. It has the same processing characteristics as wood. It can be sawed, drilled and nailed with ordinary tools. It is very convenient and can be used like ordinary wood. At the same time, it has the woodiness of wood and the water-resistant and anti-corrosion characteristics of plastic, which makes it an outdoor waterproof and anti-corrosion building material with excellent performance and very durable.

Product Advantages

(1) Waterproof and moisture-proof. The utility model fundamentally solves the problem that wood products are easy to rot, expand and deform after absorbing water in a humid and watery environment, and can be used in an environment where traditional wood products cannot be used.

(2) Insect and termite prevention, effectively eliminate insect harassment and prolong service life.

(3) Colorful, many colors to choose from. It not only has natural wood feeling and wood texture, but also can customize the required colors according to your own personality

(4) With strong plasticity, it can easily realize personalized modeling and fully reflect personalized style.

(5) High environmental protection, pollution-free, pollution-free and recyclable. The product does not contain benzene. The formaldehyde content is 0.2, which is lower than the EO standard. It is the European grading environmental protection standard. It can be recycled, greatly saving the use of wood. It is suitable for the national policy of sustainable development and benefiting the society.

(6) High fire resistance. It can be effectively flame retardant, the fire rating reaches grade B1, self extinguishing in case of fire, and does not produce any toxic gas.

(7) Good machinability, can be ordered, planed, sawn, drilled, and the surface can be painted.

(8) Simple installation, convenient construction, no complicated construction process, saving installation time and cost.

(9) No crack, no expansion, no deformation, no maintenance and maintenance, easy to clean and save later maintenance and repair costs.

(10) Good sound absorption effect and energy saving, so that the indoor energy saving is up to more than 30%.

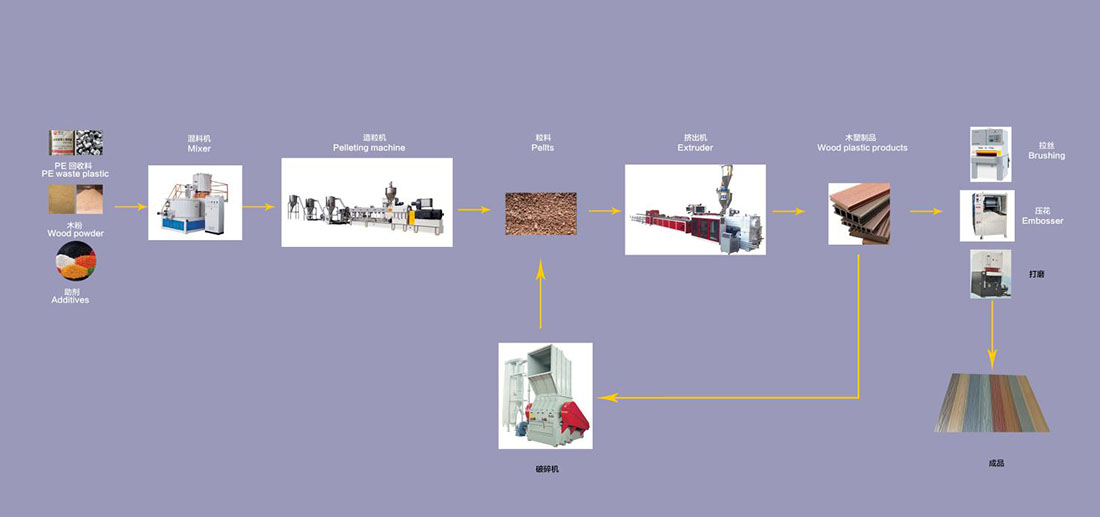

WPC (PE&PP) Wood-Plastic Floor is that the wood-plastic composite materials complete in different equipments of mixing, from play, extruding products, mixing the raw material in a certain formula, forming wood-plastic particles in the middle, and then squeezing out products.And nowadays, the two-step way is used currently, application of a wider general use conical twin screw extruderor parallel twin screw extruder granulation, and then conical twin screw extruder or single screw extruder extrusion products, mainly used in floor indoor or outdoor, parapets, tray, such as WPC (PE&PP) plastic extrusion products.

Main technical specification

|

Model |

SJZ65/132 |

SJZ72/152 |

SJZ80/156 |

|

Motor power(kw) |

37 |

45 |

55 |

|

Output (kg/h) |

150-180 |

125-300 |

200-350 |

Product image display

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.