Two founder of Jwell company (right: Mr. He Haichao Left: Mr. He Haibo)

Jwell Machinery Co., ltd is one of the biggest professional plastic extrusion equipment manufacturer in China, also one of the biggest model plastic machine manufacturing base. The company has plastic extrusion equipment manufacture experience of many year and a plenty of excellent staff in the mechanical major of engineering design, process and assembly with innovation ability. These advantages have made Jwell successful to export product to all local area and worldwide market, including Developed country Germany, USA, Japan, Spain, etc.

It is our honor to interview Jwell chairman Mr. He Haichao for China Plastic Machinery. Plz allow him to explain to us the Jwell strategic layout and future development first.

China Plastic Machinery:the local and global market in 2015 is changing complicatedly, how is Jwell operation in this environment?

Chairman He: Jwell sales in 2015 mainly equal to last year record. The sales of plastic sheet&plate equipment and recycle machine had increased steadily while the sales of plastic profile, pipe and chemical fibe machine had decreased due to the factors of macroeconomic and internal transformation &upgrading, some production line of which still grew. Jwell had growth of the breakthrough in the new career of blow molding equipment, chemical equipment co-rotating parrellel twin screw extrusion unit.

In the field of profile equipment, although PVC profile market is in many-year hard time, WPC and marble plastic career increased to some extent. Due to the characteristics of WPC and marble plastic product, in order to realise the long life time of equipment(formuale results in the wearing of screw&barrel) and lower the customer maintenance cost, we always update screw sctructure. Meanwhile we also bring in new screw&barrel machining process and equipment to further improve screw&barrel plasticising ability and life time.

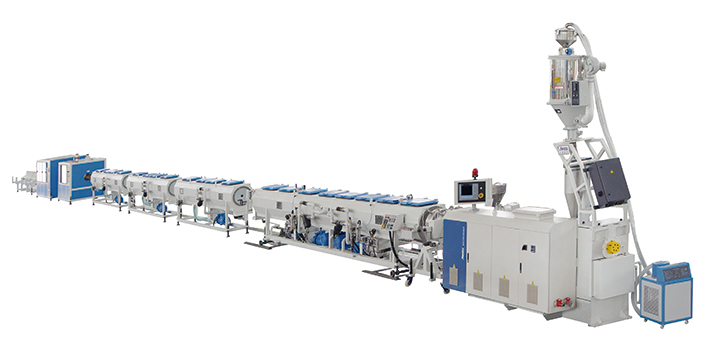

When it comes to plastic pipe machine, Jwell pipe equipment branch is actively updating the production line by reducing the electrical consumption for each unit of raw material and promoting product details in the field of soid pipe equipment. Jwell is the first manufacturer of conical twin screw extruder for making dual wall corrugated pipe equipment, whic is accepted by more and more customer in the reason of energy consumption and cost benefit.

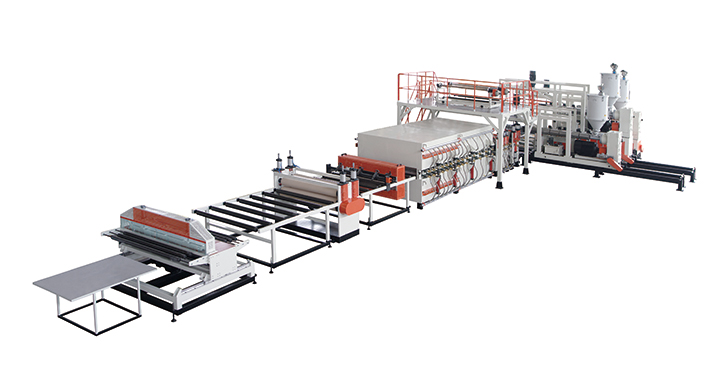

There are many application field in the plate&sheet equipment. All Jwell plate&sheet brach companies has their special skill. We're in the leading market position in the area of PET co-rotating parrellel twin screw extrusion line, PET direct drive venting single screw extrusion line, plastic marble plate extrusion line, PVC foam board extrusion line, PC optiocal sheet extrusion line, TPO PVC EVA PE waterproof sheet extrusion line, PVC Homogeneous Heart Flooring Leather Production Line and so on. We are improving the plate&sheet equipment component, i.e. T-die, roller, etc by improving machining process and quality, we not only provide them to Jwell branch and also local and global customer.

China Plastic Machinery: The develop direction of Jwell has transferred to Suzhou and Changzhou within the last several years, could U explain the developing condition of these two new zones?

Chairman He: Suzhou area is currently the biggest manufacturing base of Jwell company. It is located in Chengxiang industry zone of Taicang city with area 300mu(=0.0667 hectares). It include 6 companies right now:Suzhou Jwell MachineryCo.,ltd, Suzhou Jwell Machinery (Plate &Sheet) , Suzhou Dyun Recycling Machinery Co., Ltd, Suzhou Jwell Precision Machinery Co.,ltd., Suzhou Jwell Plastic Machinery Co.,Ltd,, Suzhou Jwell Poly Engineering Co., Ltd,. The head company has established Jwell Suzhou base in Taicang from 2007 and begin to startup it from 2008. The total factory area reaches more than 120 000 square meter and big metal machining workshop area is more than 50 000 square meter including big heat treatment workshop to undertand the big high precision in-set equipment manufacturing and assembly. The current main product is all kinds of plastic plate&sheet&water proof production line, plastic pipe production line, plastic profile production line, high precsion roller used for plastic plate&sheet&film equipment, screw&barrel used for single and twin extruder, etc.

Changzhou Jwell high-tech industrial park is another Important development strategy center of Jwell company covering area nearly 400 mu dedicated to professional plastic extrusion equipment research, manufacturing. Jwell has a group of high quality research team and mechanical&electrical testing engineer team as well as advance machining base and standrd assembly workshop. Nowaday, five companies are established in this industry zone as follow: Jwell machinery Changzhou Co., Ltd, Changzhou Jwell extrusion Co., Ltd, Changzhou Jwell Pipe Co., Ltd, Changzhou Jwell chemical equipment in set Co., Ltd, China-Italion joint venture Dage Machinery Co., Ltd. The manufacturing scope include Jwell mature product, i.e. plastic pipe, profile, plate&sheet extrusion line and parrellel twin screw extrusion machine and raw material treating unit. With more and more new company joining in this industry zone, the zone product system will be more systematic including raw material conveying, mixing, pelletizer, extrusion machine and other complete unit so as to have capacity of the "one-stop" work style services for the plastic industry customers.

China plastic machinery: Two factories has significance of strategic for Jwell future developing, could U plz introduce current developing status?

Chairman He: After 8 year work, the research&innovation ability and manufacturing ability has been promoted to big extent every year.Rely on the technical experience collection in plastic machinery industry and cooperation with research unit of concerned high school, Suzhou branch companies has obtained many reputation, i.e. high and new technology enterprise, provincial research and development center. Suzhou Jwell has focused on technology innovation and new product development, paid more attention to customer's requirement and speeded up on creating step for last two years. We have succeed in providing 1600mm diameter or more super diameter solid pipe production line, RTP high pressure coating pipe production ine, 8m width or more waterproof sheet production line, stone paper extrsion line, solar cell/ lithium battery membrane production line, optical sheet&film extrusion line, etc. These production lines have high automation, technical content, product added value so as to creat more value for customer.

There are 5 branch companies in Changzhou Jwell zones. The Changzhou Jwell chemical complete equipment Co., Ltd and Changzhou Jwell pipe equipment manufacturing Co., Ltd is one of Jwell complete set equipment branch company. The first one mainly manufactures high standard co-rotating parrellel twin screw extruder and relative complete production line. Through technical innovation and integration, screw torch rating wth full local equipmen has excess 12 N.m/cm3, the max screw RPM has reached 1200rpm. The screw inner oter diameter verse include 1.55 standard and also 1.66 deep slot machine type. It can be concluded that Jwell parrellel twin screw extruduer has been improved to big extent from local technology level.

The second one is the second Jwell branch in the name of Jwell pipe equipment manufacturing Co., Ltd. This name means that this company focus on plastic solid pipe equipement and relative product, which is a huge market. The company aims to make high standard plastic machine, bring in and improve product structure, performance. By the means of advance technology, company aims to develop high class plastic machine market in local and global market.

China plastic machinery: the competition of plastic machinery is very fierce, Jwell has been top extruder company after years developing, could u tell how to maintain and promote Jwell branch influence for new strategic center of gravity?

Chairman He: in order to serve customer better and creat Jwell brand value, Jwell place big investment of human force and machine cost on the quality and precison improvement of key parts of extrusion line. This include core part quality promotation and updating, step-by-step company product technical updating, reseach investment, excellent staff employing, refresh equipment, etc.

Last year suzhou area company equips super mirror roller dust-free polishing workshop and introduces Japanese technology super mirror roller disc type precision CNC grinding equipment, offers guarantee products quality control for optical transparent sheet/film production line. Striving of perfect the manufacturing process obtains the recognition of industry experts at home and abroad, the current global top brand of plastic extrusion equipment manufacture also equip our precision roller with lines running in Germany, the United States and more than 10 countries and regions in the world.

In Changzhou area, parallel twin-screw extruder not only greatly improves the screw torque from the product technology, also the whole machine is equipped with high speed high torque transmission box, high-precision cylinder and high-precision thread component, high strength core shaft and suitbale feed matching technology improvement for high speed high torsional model. Huge advances in technology have significantly improve production output and product quality , finished product comprehensive energy consumption of production per unit also decreased obviously. Specific to not identical characteristics of each line , Changzhou pipe line company goes to understand each pipe standards, the use of the environment, the actual status of the customer's construction and other details, and communicate with people from different backgrounds to constantly improve our products.

"diligence&innovation" is the company culture, Jwell machinery has been done like this for more than 10 years. We want to make this spirit live on and constantly strive to make every our customers get the highest price/performance ratio equipment to create higher brand value.

China Plastic machinery : what is the most critical to Jwell's achievements?

Chairman He: the key is people, no matter how advanced the technology is , talent staff is the key of the success forever. Jwell achievements you see can't be performed by a few people but by our outstanding team with many years hard work.

Jwell company has always been focusing on talent selection and cultivation, in addition to various universities recruitment, the company also pays attention to the internal training of enterprise, our Jwell class is through the cooperation with colleges to develop first-class talents with self learning ability, innovation spirit and innovation ability. To cultivate a batch of reserved talent with craftmanship, the company has been advocating "Dedicated will be rewarded".

Jwell company also have their own ideas for appointment of talent. Jwell company is made up of 18 professional equipment production companies, that is to say we need more enterprise managers, but the management level of these general managers is not only a professional managers, we are looking for partners with same aspirations who agree with the enterprise idea deligence, innovation, Jwell company has become the the incubator of general manager. Good talent scout not only has inside to find talent, but also can give talent space to work well. Over these years, Jwell company have sprung up a group of outstanding management personnel, each person has their bright spot, companies under their management is also full of vitality.

Jwell changzhou factory is the high-tech industrial park towards future under huge investment of Jwell company , 5 companies were opened last year, we always encourage and support those partners who have common aim and spirit of struggling, changzhou area will be the place where the entrepreneurs show skill, so I prefer to call it "startup zone", I'm also looking forward to have more energetic talents and more like-minded people to cooperate with Jwell and work together.

China plastic machinery: would you please introduce Jwell future development plans?

Chairman He: plastics processing enterprises has been the high energy consumption, labor-intensive enterprises, energy saving, high efficiency is always common goal of all plastic industry enterprise . As a mechanical equipment manufacturing enterprise, product continuous improvement is our long-term task. As a result, the energy saving efficiency is also the main direction of our equipment. With the continuous application of the new material and new technology, more possibility is provided to equipment energy-saving and realization of high output and efficiency.

As to the implementation of the industry 4.0 and the concept of Internet +, Jwell machinery is actively promoting and practice all the time. As early as Chinaplas exhibition in May 2015 in guangzhou, Jwell company held plastic extrusion industrial 4.0 press conference, and live demonstrate remote monitoring system based on the mobile end. Industry 4.0 is divided into two parts for us, one is own enterprise industry promoting 4.0, the core is to promote the customer visualization and real-time inspection for the product manufacture and the whole maintenance process so as to improve customer satisfaction. The other part is to help customers achieve unmanned management of manufacturing factory, improve equipment reliability&automation level, remote monitoring, ERP integration, etc.

Not easily speaking out of future, because we have a long way to go, in the field of plastic extrusion equipment segment, we gathered a group of Jweller with rich experience, full of vitality and passion. With same goal and desire, we hope that China's extrusion equipment can catch up with the trend of the world.

Post time: Jul-01-2017