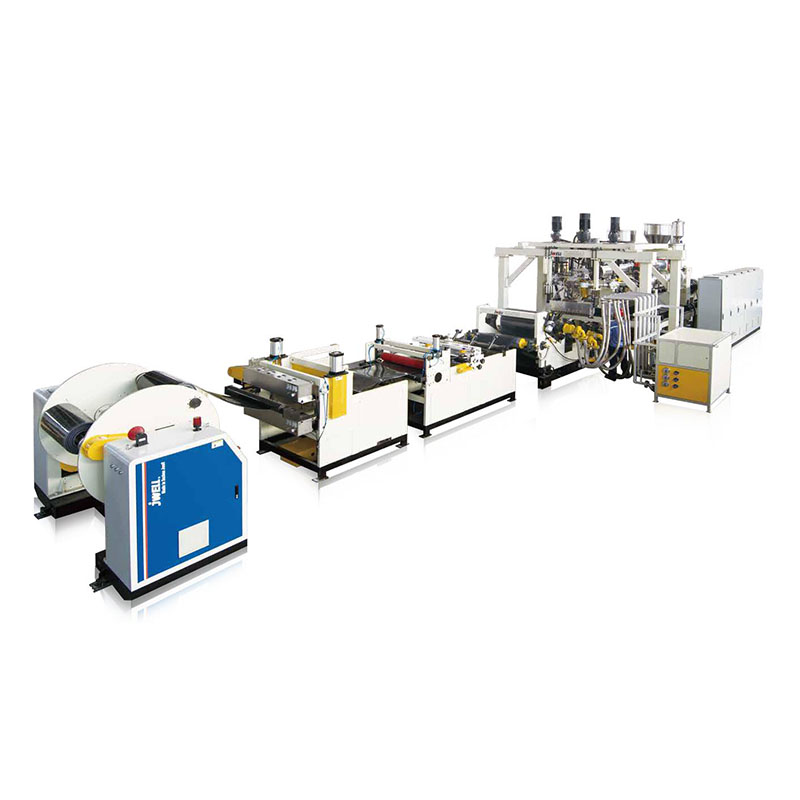

Wholesale China thermoforming and packing sheet Extrusion Machine Factory Quotes – TPO+PP Foam Composite Sheet Production Line – JWELL

Wholesale China thermoforming and packing sheet Extrusion Machine Factory Quotes – TPO+PP Foam Composite Sheet Production Line – JWELL Detail:

It is successfully developed by JWELL Machinery, adopts special structure of TPO screw, plasticizing evenly, unique composite processing method, composite products have high bonding strength, No tensile deformation, formaldehyde-free, it is Jwell’s company according to car interior materials’s field recommends another domestic advanced composite sheet production line, this composite material has flexible operation, high efficiency of compositing, with the advantage to complete the treatment of the TPO surface layer’s lines once time, with the basic material to hot pressing and compositing together once time, it is total different from past composite method, this product is widely applied in high class inner decoration, ceiling, pipe of the car, and so on.

Main technical specification

|

Model |

Products width(mm) |

Products thickness(mm) |

Capacity(kg/h) |

|

JW100/33 |

2000 |

0.5 |

120 |

|

JW120/33 |

1500 |

0.5 |

220 |

Note: The specifications are subject to change without prior notice.

Composition of plastic extrusion machine

The main machine of a plastic extrusion machine is an extruder, which is composed of an extrusion system, a transmission system and a heating and cooling system.

Extrusion system

The extrusion system includes Extruder, Feeding system, Screen changer, Metering pump, T-die. The plastic is plasticized into a uniform melt through the extrusion system, and is continuously extruded by the screw under the pressure established in the process.

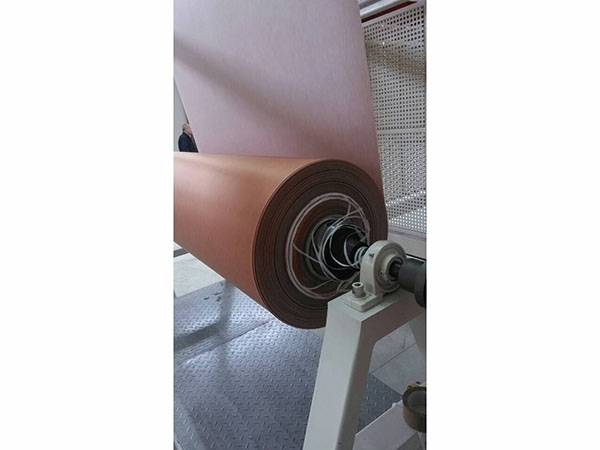

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Wholesale China thermoforming and packing sheet Extrusion Machine Factory Quotes – TPO+PP Foam Composite Sheet Production Line – JWELL , The product will supply to all over the world, such as: Sao Paulo, Lesotho, Kuwait, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.