Wholesale China Single Screw Pvc Pipe Machine Factory Quotes – PE/PP Double Wall Corrugated Pipe Extrusion Machine(High-speed Single Screw Extruder ) – JWELL

Wholesale China Single Screw Pvc Pipe Machine Factory Quotes – PE/PP Double Wall Corrugated Pipe Extrusion Machine(High-speed Single Screw Extruder ) – JWELL Detail:

Several features of double wall Corrugated Pipe bellows

Strong resistance to external pressure

The outer wall has an annular corrugated structure, which greatly enhances the ring stiffness of the pipe, thus enhancing the resistance of the pipe to soil load. In this performance, HDPE Double wall corrugated pipe has obvious advantages compared with other pipes.

Low project cost

Under the condition of the same load, HDPE Double wall corrugated pipe only needs a thinner pipe wall to meet the requirements. Therefore, compared with the solid wall phase pipe of the same material specification, about half of the raw materials can be saved, so the cost of HDPE Double wall bellows is also low. This is another outstanding feature of the pipe.

Convenient construction

Due to the light weight of HDPE Double wall bellows and convenient handling and connection, the construction is fast and the maintenance is simple. In the case of tight construction period and poor construction conditions, its advantages are more obvious.

Small friction coefficient and large flow

HDPE Double wall corrugated pipe made of HDPE can pass through greater flow than other pipes with the same diameter. In other words, HDPE Double wall bellows with relatively small diameter can be used under the same flow requirements.

Low temperature and impact resistance

The embrittlement temperature of HDPE Double wall bellows is – 70 ℃. In general, it is unnecessary to take special protective measures during construction under low temperature (- above 30 ℃), which is convenient for construction in winter, and HDPE Double wall bellows has good impact resistance.

Good chemical stability

Because HDPE molecules have no polarity, they have excellent chemical stability. Except for a few strong oxidants, most chemical media do not damage them. Generally, the soil, electricity and acid-base factors in the use environment will not damage the pipeline, breed bacteria and scale, and its circulation area will not decrease with the increase of operation time.

Long service life

The service life of HDPE Double wall bellows can reach more than 50 years without sunlight and ultraviolet rays.

Excellent wear resistance

Tests in Germany have proved that the wear resistance of HDPE is even several times higher than that of steel pipe.

Proper deflection

A certain length of HDPE Double wall bellows can be slightly flexed axially, not affected by a certain degree of uneven settlement of the ground, and can be directly laid in a slightly non straight groove without pipe fittings, etc.

Performance and advantages of our equipment: The corrugated pipe line is the 3rd generation of improved product of Jwell. The output of the extruder and the production speed of the pipe are greatly increased by 20-40% compared with the previous product. Online belling can be achieved to ensure the performance of the formed corrugated pipe products. Adopts Siemens HMI system.

1. The newly designed closed molding machine adopts a special high-efficiency cooling system for forming aluminum modules, which greatly improves the cooling efficiency in the production of corrugated pipe products;

2. High-speed, high-output single-screw extrusion machine supporting a professional design of the corrugated pipe extrusion mould to achieve large-scale stable extrusion;

3. Good interchangeability of the module; the aluminum forming module uses LY12 high-quality alloy aviation aluminum material with copper content ≥ 5%, precision pressure casting process, high density material, no light pores,long-term use is not easily deformed. Can customize various module waveform schemes according to the user’s requirements;

4. Supporting automatic DWC cutter, computer control, accurate cutting position, stable running and easy to operate.

Main technical specification

|

Model |

Pipe diameter |

Max speed |

Capacity |

Total power |

|

JWSBL-300 |

110-300mm |

5m/min |

500kg/h |

440kw |

|

JWSBL-600 |

200-600mm |

5m/min |

800kg/h |

500kw |

|

JWSBL-800 |

200-800mm |

3m/min |

1000kg/h |

680kw |

|

JWSBL-1000 |

200-1000mm |

2.5m/min |

1200kg/h |

710kw |

|

JWSBL-1200 |

800-1200mm |

1.5m/min |

1400kg/h |

800kw |

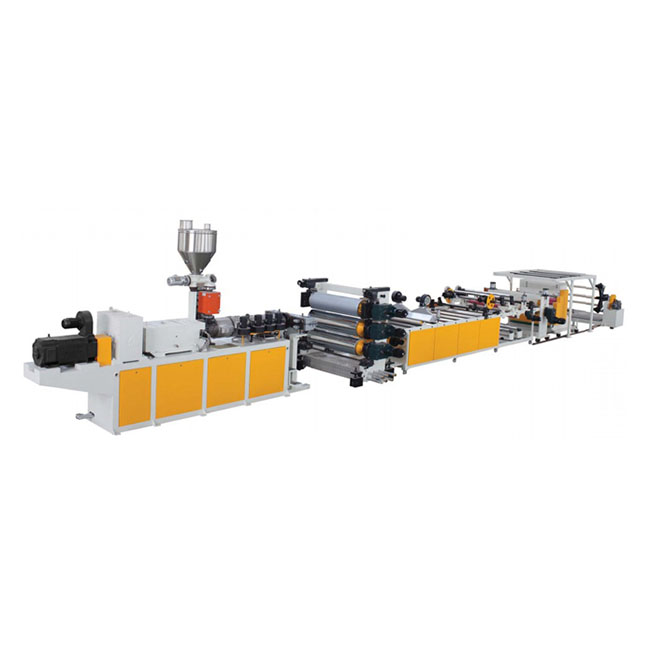

Product image display

Product detail pictures:

Related Product Guide:

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for Wholesale China Single Screw Pvc Pipe Machine Factory Quotes – PE/PP Double Wall Corrugated Pipe Extrusion Machine(High-speed Single Screw Extruder ) – JWELL , The product will supply to all over the world, such as: Vietnam, Botswana, United Arab emirates, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.