Wholesale China Sheet Extruder Factory Quotes – TPU/ABS Laminate Sheet Extrusion Line – JWELL

Wholesale China Sheet Extruder Factory Quotes – TPU/ABS Laminate Sheet Extrusion Line – JWELL Detail:

Main technical specification

|

Model |

Products width(mm) |

Products thickness(mm) |

Capacity(kg/h) |

|

JW130/38+JW90/38 |

2400 |

1.5-10 |

700-800 |

|

JW120/38+JW80/38 |

1800 |

1.5-10 |

500-600 |

Note: The specifications are subject to change without prior notice.

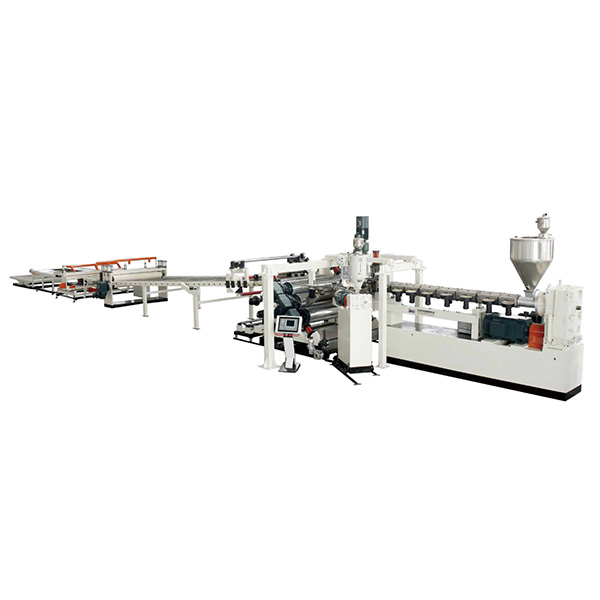

Product image display

For the thin-walled high-efficiency roller, the surface shell thickness is only 50%-70% of the standard roller; by reducing the area of the strikes, and enlarging the contact area with cooling water, the thermal conversion efficiency is increased. And to offset the roller rigidity, the overall circular runner design is adopted to increase the intensity of the roller. Under the same working condition, the thin wall high efficiency roller boosted plate and sheet line output by 20% to 50%.

Material heat treatment

● Quenching with Subsequent tempering, ensures the density of the structure.

● Outer surface deeply quenched, the hardness can be reached HRC 50~55.

● Surface electrolyze hard chromed, the hardness can be reached HRC 58~65.

Surface treatment

● Mirror roller, super mirror roller grinding and polishing processing.

● Different kinds of roller surface treatments are available, such as leather veins, matt, mist, frosting, net veins and etc.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for Wholesale China Sheet Extruder Factory Quotes – TPU/ABS Laminate Sheet Extrusion Line – JWELL , The product will supply to all over the world, such as: Niger, Jakarta, Albania, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!