Wholesale China PVC Decoration Sheet Extrusion Machine Quotes Pricelist – PP and Calcium Powder Environmental Protection Sheet Extrusion Line – JWELL

Wholesale China PVC Decoration Sheet Extrusion Machine Quotes Pricelist – PP and Calcium Powder Environmental Protection Sheet Extrusion Line – JWELL Detail:

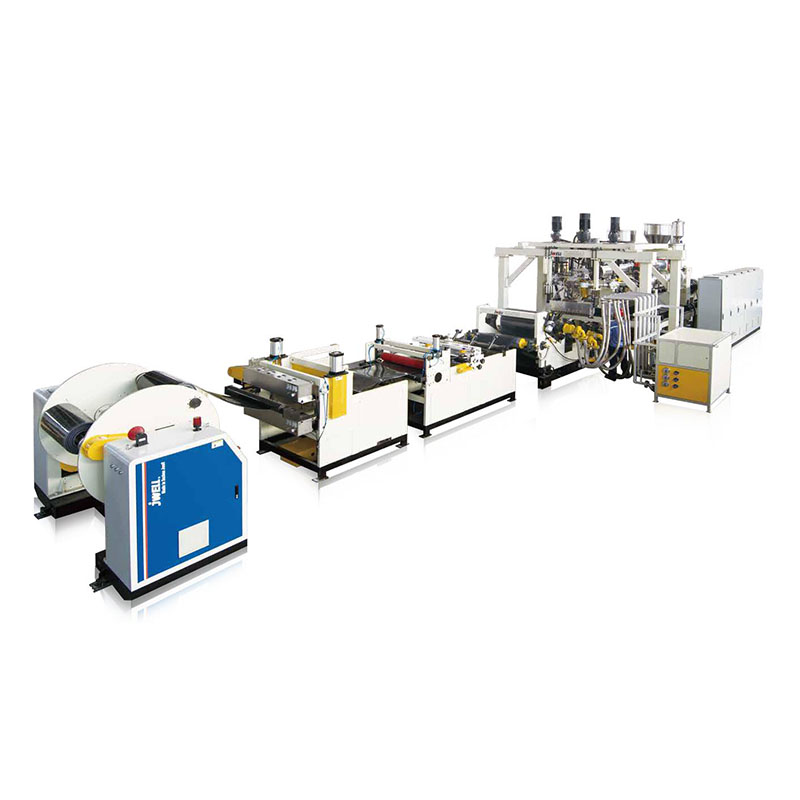

PP+CaCo3 environmentally-friendly sheet extrusion line

It developed by Jwell company uses the three extruders for 3 or 4 layers co-extrusion. This line adopts the Jwell latest designed PP+CaCo3 vented screw and the PLC computer controlling device and automatically thickness detection device so that the machine can maximize the percentage of the CaCo3 in the sheet production to reduce the cost of the sheet and the sheet produced can gain the good physical properties and further processing abilities. It is the most advanced sheet machine in China.

Main technical specification

|

Model |

JW-120/100/45-1500 |

|

Products Width |

1320mm |

|

Products thickness |

0.3mm |

|

Layer structure |

A/B/C/A |

|

Capacity |

800kg/h |

Note: The specifications are subject to change without prior notice.

Display of finished products

Composition of plastic extrusion machine

The main machine of a plastic extrusion machine is an extruder, which is composed of an extrusion system, a transmission system and a heating and cooling system.

Extrusion system

The extrusion system includes Extruder, Feeding system,Screen changer, Metering pump,T-die. The plastic is plasticized into a uniform melt through the extrusion system, and is continuously extruded by the screw under the pressure established in the process.

Screw and Barrel: It is the most important part of the extruder. It is directly related to the application range and productivity of the extruder. It is made of high strength and corrosion resistant alloy steel.The barrel cooperates with the screw to achieve the crushing, softening, melting, plasticizing, venting and compacting of the plastic, and continuously and uniformly conveys the rubber to the molding system.

Feeding system: its function is to evenly transport different forms of plastics to the hopper of the extruder.

Screen changer: Its function is to remove all kinds of impurities in plastic

Metering pump: Equipping a pump in front of the extruder, checking pressure before the pump and controlling the speed of extrusion, which can minimizing pulsation and irregular material feeding and ensures the polymer is smoothly extruded and continuously delivered to the die head. The shell of the pump adopts high-quality alloy-steel and

the gear uses quenched chrome steel or other high-grade metallic materials which ensures high efficiency and leakage-proof.

T-die: The function of the T-die is to convert the plastic melt that rotates into parallel and linear movement, which is evenly and smoothly introduced.

Transmission system

The function of the drive system is to drive the screw and supply the torque and speed required by the screw in the extrusion process. It usually consists of a motor, a reducer and a bearing.

Heating and cooling device

Heating and cooling are necessary conditions for the plastic extrusion process to take place.

1. The extruder usually uses electric heating, which is divided into resistance heating and induction heating. The heating sheet is installed in the body, neck and head. The heating device heats the plastic in the cylinder externally to increase the temperature to reach the temperature required for the process operation.

2. The extruder cooling device is set to ensure that the plastic is in the temperature range required by the process. Specifically, it is to exclude the excess heat generated by the shear friction caused by screw rotation, so as to avoid the temperature being too high to make the plastic decompose, scorch, or shape difficult. The barrel cooling is divided into two types: water cooling and air cooling. Generally, small and medium-sized extruders are more suitable for air cooling, and large-sized ones are mostly water-cooled or combined with two forms of cooling.

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Wholesale China PVC Decoration Sheet Extrusion Machine Quotes Pricelist – PP and Calcium Powder Environmental Protection Sheet Extrusion Line – JWELL , The product will supply to all over the world, such as: Indonesia, Peru, Luxemburg, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers' benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.