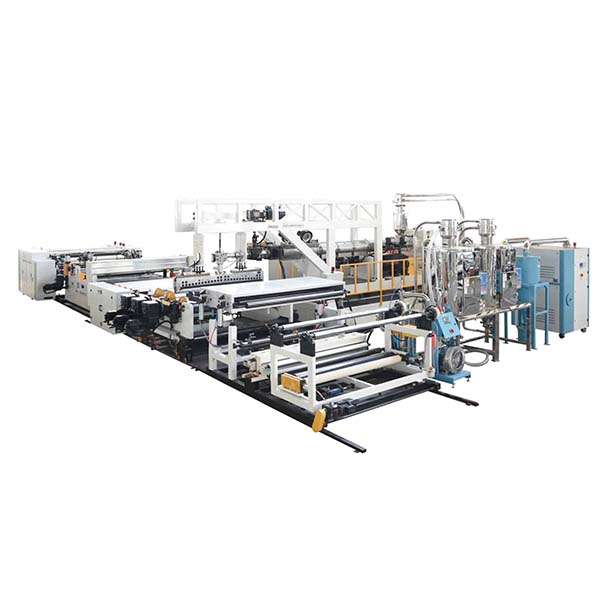

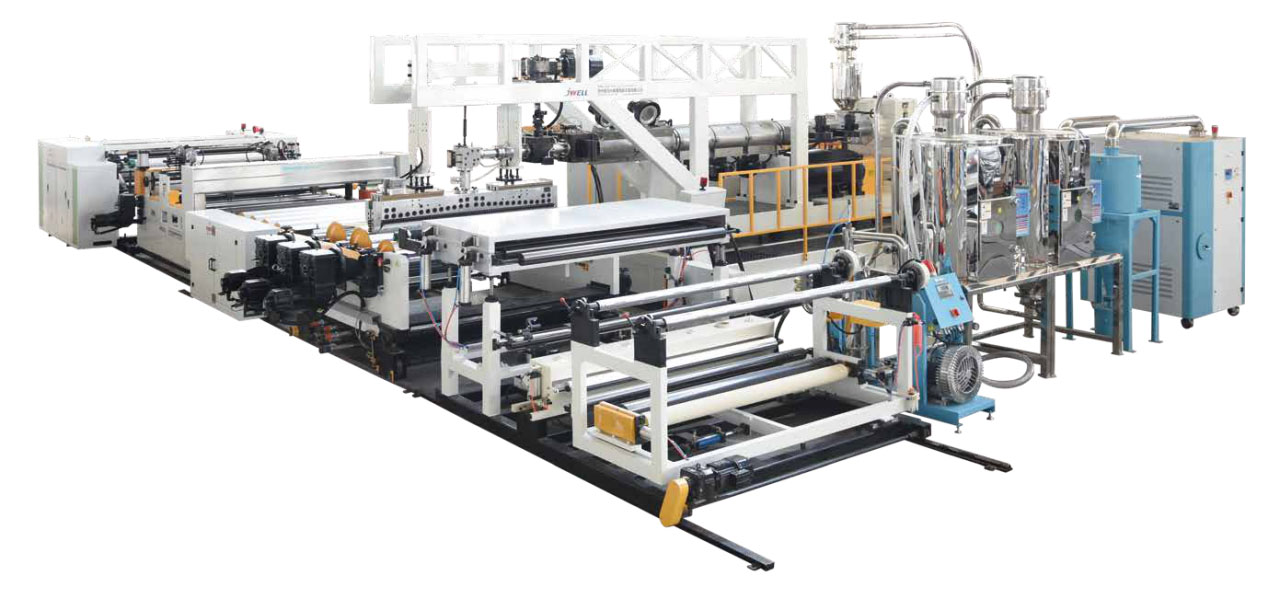

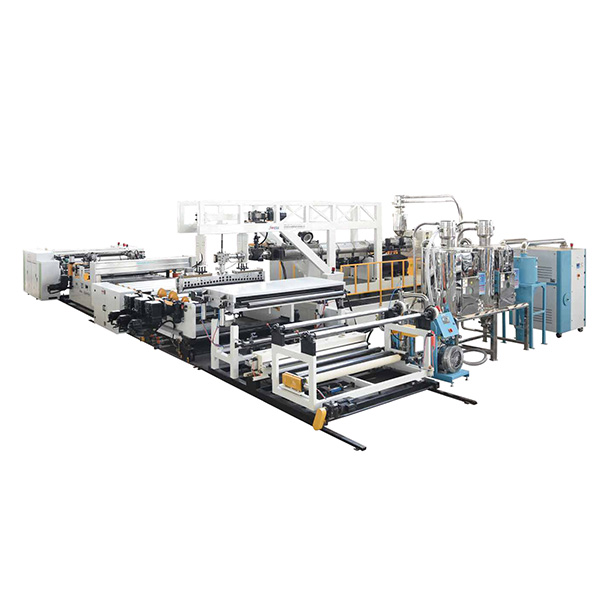

Wholesale China PVB Film Extrusion production line Manufacturers Suppliers – TPU Film /Hot Melt Film Extrusion Machine – JWELL

Wholesale China PVB Film Extrusion production line Manufacturers Suppliers – TPU Film /Hot Melt Film Extrusion Machine – JWELL Detail:

Product description

TPU material is thermoplastic polyurethane, which can be divided into polyester and polyether. TPU film has excellent characteristics of high tension, high elasticity, high wear resistance and aging resistance, and has the excellent characteristics of environmental protection, non-toxic, mildew proof and antibacterial, biocompatibility, etc. It is widely used in shoes, clothing, inflatable toys, water and underwater sports equipment, medical equipment, fitness equipment, car seat materials, umbrellas, bags, packaging materials, and can also be used in optical and military fields.

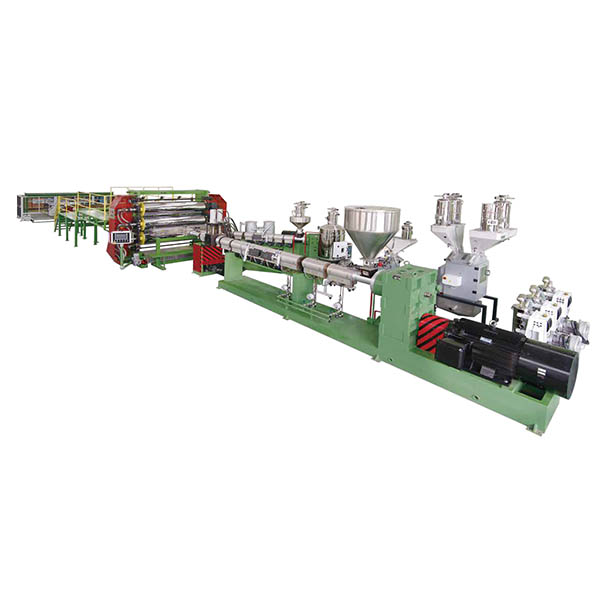

TPU Film /Hot Melt Film Extrusion Machine adopts high-speed extrusion calendering and casting. The product quality is excellent and controllable. The thickness of the product is 0.01-2.0 mm, and the width is 1000-3000 mm. It is suitable for TPU film products with transparent color, frosting, fog surface and multilayer composite.

Casting system is a step of of vital importance in film stretching line. The finish film quality after stretching will be finally based on master precsion of casting system. This casting roller manufactured by Jwell Machinery Co.,LTD has already been used a lot in high level stretching line imported from Europe and its performance in practical application obtains unanimous approval and favorable comment from customers.

Features

● Max diameter 1600mm

● Variable diameter alternating spiral flow channel

● Surface temperature precision±0.5℃

● High efficiency heat exchange technology performance

● High precision dynamic balancing correction

● High quality mirror face processing

● Anti-corrosion treatment of spiral flow channel

● Roller cylindricity, concentricity both ≤0.005mm;

● Roller surface hard chromium plated, coating thickness is 50 ~ 80 um

● roller surface treatment: mirror polished, super finishing mirror, matt, mist and anti adhesive surface;

● Speed: max. 800 m/min;

● Overall deformation: < 0.05 mm at full load

● Best dynamic balance: Q = 3.2

Main technical specification

|

Model |

Products width |

Products thickness |

Capacity |

|

JWS120/36 |

1000-3000mm |

0.02-2mm |

200-300kg/h |

|

JWS130/36 |

1000-3000mm |

0.02-2mm |

300-400kg/h |

|

JWS150/36 |

1000-3000mm |

0.02-2mm |

400-500kg/h |

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for Wholesale China PVB Film Extrusion production line Manufacturers Suppliers – TPU Film /Hot Melt Film Extrusion Machine – JWELL , The product will supply to all over the world, such as: Dominica, Morocco, Bahamas, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!