Wholesale China PE Sheet Extrusion production line Quotes Pricelist – PVC composite floor leather extrusion machine – JWELL

Wholesale China PE Sheet Extrusion production line Quotes Pricelist – PVC composite floor leather extrusion machine – JWELL Detail:

Description

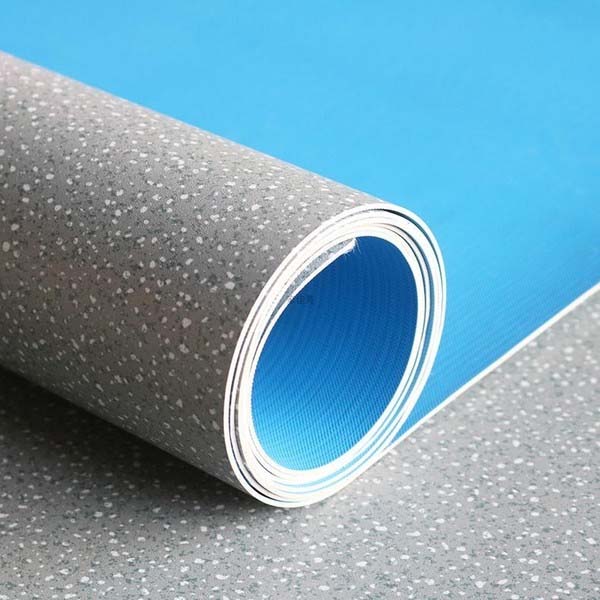

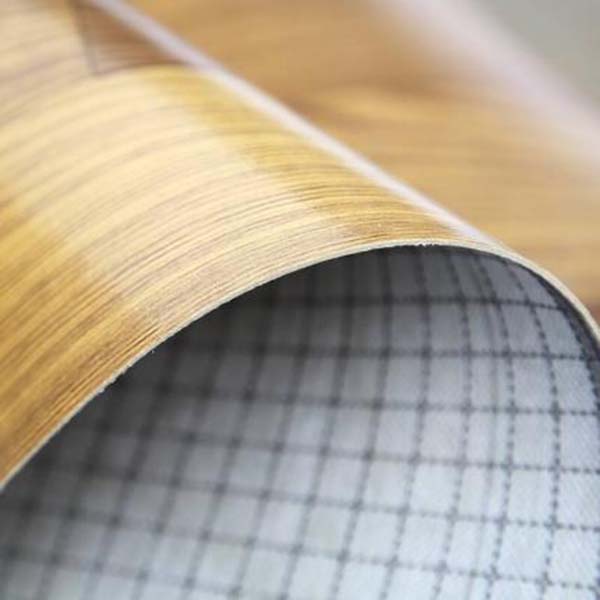

■ Good decoration. PVC floor leather can suppress a variety of colors, stone patterns, wood floor patterns, grass patterns, etc. the colors are realistic, the lines are clear, and the patterns are rich and diverse, which can meet the personalized needs of different hobbies.

■ Environmentally friendly and non-toxic. PVC materials and calcium carbonate are the main materials used in PVC floor leather. They are environmentally friendly and non-toxic renewable resources. They are composed of tap water pipes, tableware and medical infusion pipe bags, which are widely used in life. General PVC floor leather is free of formaldehyde, benzene, phenol and other harmful chemicals, non-toxic and radiation free.

■ PVC floor leather is easy to install and maintain. The installation of PVC floor leather does not need cement mortar, which is fast and convenient. Easy to clean, clean with wet mop, not afraid of blisters, acid and alkali resistance and other chemicals.

■ Comfortable feet. The surface structure of PVC floor leather is fine and compact. It is equipped with high elastic foam cushion, which has strong bearing force. Glassware is not easy to break when it falls to the ground, and the foot feeling is comfortable. It is very suitable for the elderly and children.

■ PVC floor leather also has the characteristics of wear resistance, high elasticity, super impact resistance, anti-skid, fire prevention, waterproof, sound absorption, antibacterial and so on.

There are three types according to structure:

1. Non substrate floor leather is mostly composed of plastics with different material properties of surface layer and bottom layer. The surface layer is wear-resistant, the bottom layer is tensile and inelastic;

2. The bottom lining of floor leather with base material is glass fiber felt, asbestos paper or synthetic fiber woven case, and finally a transparent wear-resistant layer is attached to the surface layer;

3. Elastic floor leather is added foam plastics or foam rubber cushion under the bottom lining.

PVC floor leather is affordable, non slip, environmentally friendly and fashionable. It is more suitable for modern people’s life taste. It is the only choice for decoration in families, offices, schools and other places.

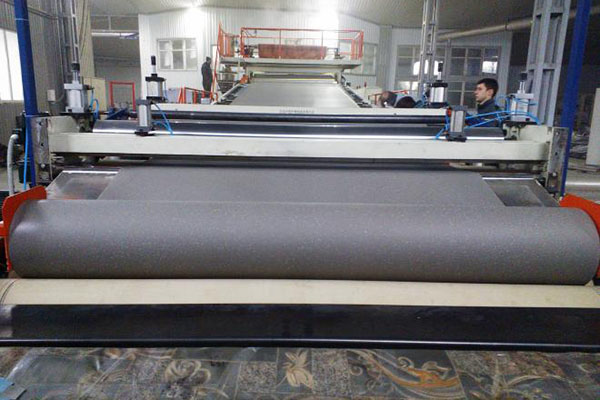

The structure of this production line is simple, and convenient to operation.According to customers requirement,equipped with different components,used for producing single layer,multi-layer composite production and also can be equipped with unreeling unit,used for producing inner strengthen production or surface compound non-woven fabrics and PVC decoration film, etc.

Main technical specification

|

Model |

Double layers |

Three layers |

|

Products width |

1200-2000mm |

2000-3000mm |

|

Products thickness |

0.8-3mm |

1-3mm |

|

Extruder model |

SJZ65/132-SJZ80/156 |

SJZ65/132-SJZ80/156-SJZ65/132 |

|

Capacity |

500-550kg/h |

600-750kg/h |

|

Main motor power |

37kw/55kw |

37kw/55kw/37kw |

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for Wholesale China PE Sheet Extrusion production line Quotes Pricelist – PVC composite floor leather extrusion machine – JWELL , The product will supply to all over the world, such as: New Zealand, Saudi Arabia, Uruguay, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!