Wholesale China Ixpe Foaming Sheet Extrusion Machine Quotes Pricelist – High Speed Aluminum Plastic Composite Panel Extrusion Line – JWELL

Wholesale China Ixpe Foaming Sheet Extrusion Machine Quotes Pricelist – High Speed Aluminum Plastic Composite Panel Extrusion Line – JWELL Detail:

Application and Feature

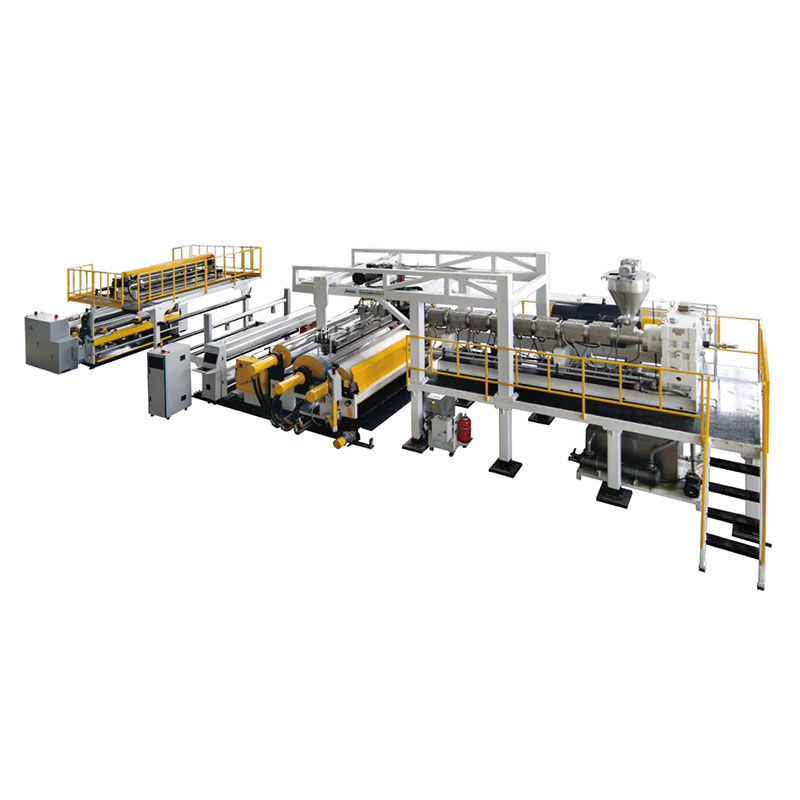

Combining traditional processing technology and practical experience, JWELL machinery Co., Ltd. develops high speed flame retardant grade ACP board. the max output can be 2500kg/h, line speed is 10m/min, width is 900- 2000mm, aluminum foil thickness is more than 0.18mm.

Also, we are supplying normal ACP line with output range 500-800kg/h, maxim line speed 5m/min, suitable product width 900-1560mm, aluminum foil thickness 0.06-0.5mm.

Main technical specification

|

Model |

Products width(mm) |

thickness(mm) |

Capacity(kg/h) |

|

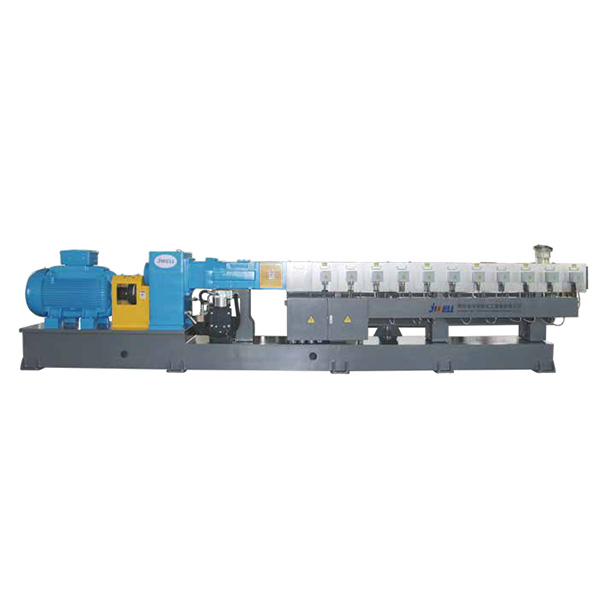

JWE135/48 (Twin screw extruder) |

900-2000 |

2-6 |

2000-2500 |

|

JWS170/35 (Singe screw extruder) |

900-1220 |

1-6 |

500-600 |

|

JWS180/35 (Singe screw extruder) |

900-1560 |

1-6 |

700-800 |

Note: The specifications are subject to change without prior notice.

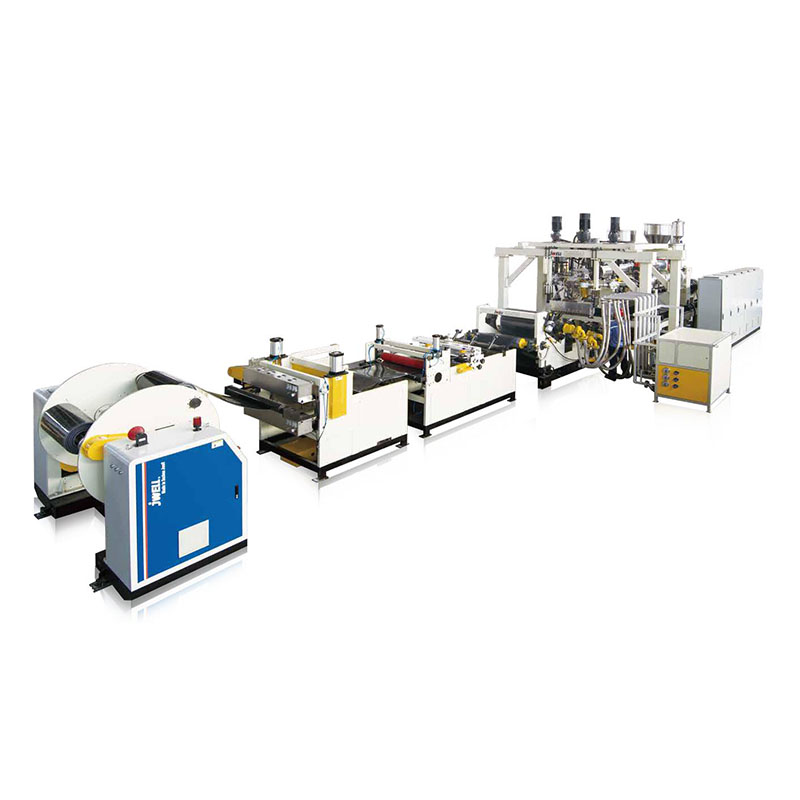

Product image display

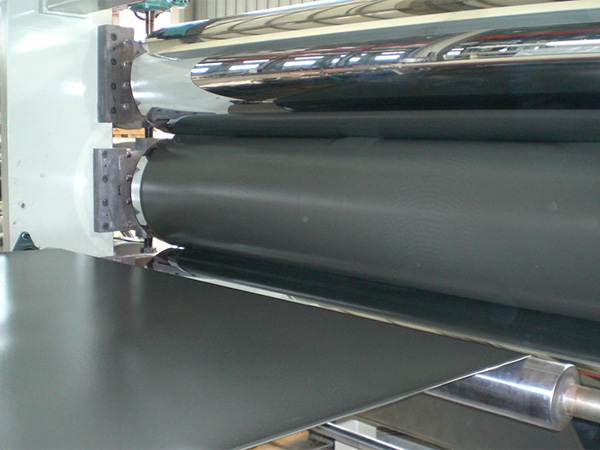

Roller surface treatment for ACP sheet

● Quenching with Subsequent tempering, ensures the density of the structure.

● Outer surface deeply quenched, the hardness can be reached HRC 50~55.

● Surface electrolyze hard chromed, the hardness can be reached HRC 58~65.

● Mirror roller, super mirror roller grinding and polishing processing.

● We can process different kinds of roller surfaces, such as leather veins, matt, mist, frosting, net veins. And we can make the roller according to the client’s samples.

● The surface sprayed by Teflon, different kinds of rubber rollers.

● Pouble (double) shells, insicle(inside) sprial tunnel design, pefect cooling efficiency.

● Adope(adopt) the thermal interference type, high strength, crowning to compensate of bending the sheet/ plate/ film final produts tolerance.

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Wholesale China Ixpe Foaming Sheet Extrusion Machine Quotes Pricelist – High Speed Aluminum Plastic Composite Panel Extrusion Line – JWELL , The product will supply to all over the world, such as: Estonia, USA, Germany, We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.