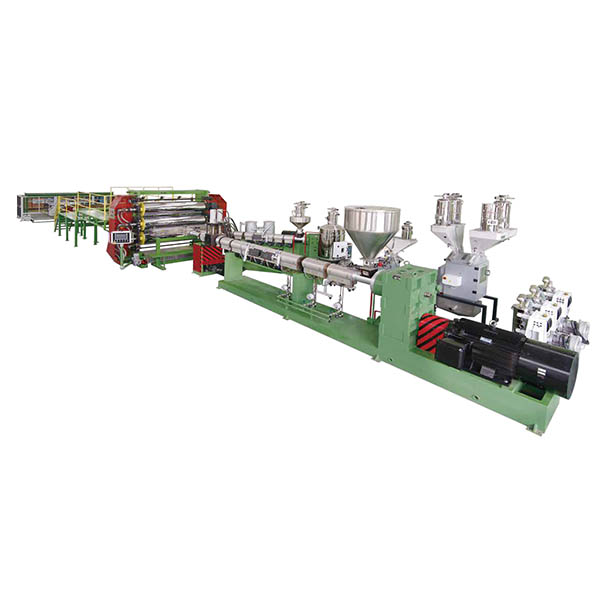

Wholesale China GPPS Plate Extrusion production line Manufacturers Suppliers – PVC Imitation Marble Board Extrusion Line – JWELL

Wholesale China GPPS Plate Extrusion production line Manufacturers Suppliers – PVC Imitation Marble Board Extrusion Line – JWELL Detail:

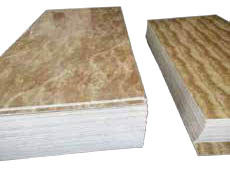

PVC Imitation Marble Board:

a. The surface of the board is covered with imitation marble pattern, or heat transfer imitation marble pattern and UV curing treatment, good scratch resistance.

b. Board with variety of color,it’s convenient to construct.

c. Replace the natural stone such as marble in the interior wall decoration, good ageing resistance, UV resistance, yellowing resistance, green environmental protection, no radiation.

Main technical specification

|

Model |

Material |

Extruder specification |

Products width(mm) |

Thickness(mm) |

Capacity(kg/h) |

|

SJZ80/156 |

PVC |

JWS150/38; 90/35 |

1220 |

4-6 |

600 |

Note: The specifications are subject to change without prior notice.

Product image display

Mirror roller surface treatment

● Quenching with Subsequent tempering, ensures the density of the structure.

● Outer surface deeply quenched, the hardness can be reached HRC 50~55.

● Surface electrolyze hard chromed, the hardness can be reached HRC 58~65.

● Mirror roller, super mirror roller grinding and polishing processing.

● We can process different kinds of roller surfaces, such as leather veins, matt, mist, frosting, net veins. And we can make the roller according to the client’s samples.

● The surface sprayed by Teflon, different kinds of rubber rollers.

● Pouble(double)shells, insicle(inside) sprial tunnel design, pefect cooling efficiency.

● Adope(adopt) the thermal interference type, high strength, crowning to compensate of bending the sheet/ plate/ film final produts tolerance.

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Wholesale China GPPS Plate Extrusion production line Manufacturers Suppliers – PVC Imitation Marble Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Orlando, Argentina, Zambia, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!