TPU High-low Temperature/High-elastic Film Co-extrusion Line – JWELL

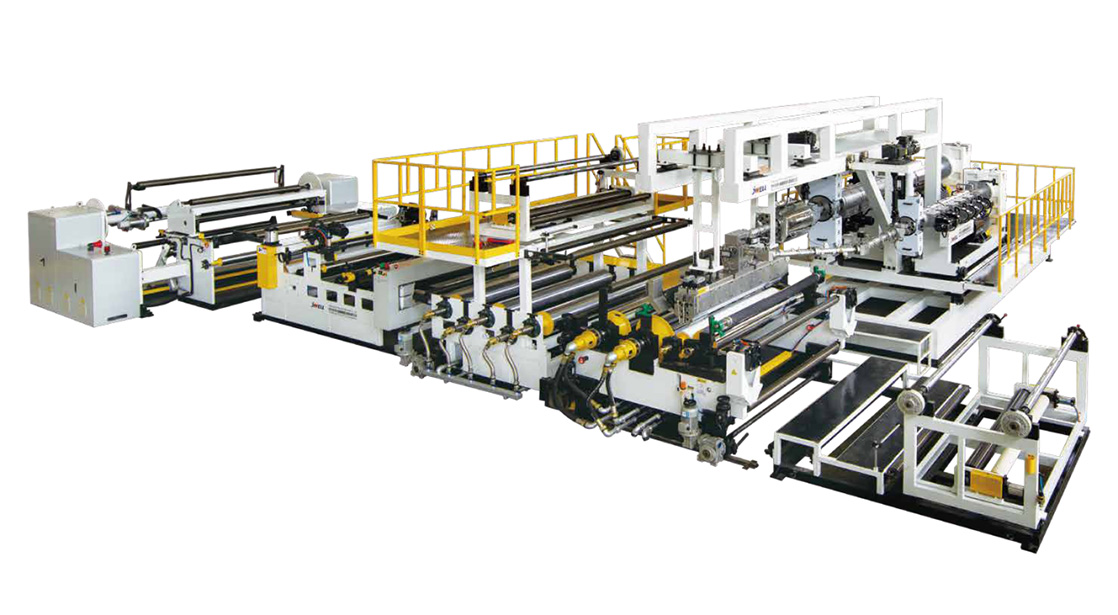

TPU High-low Temperature/High-elastic Film Co-extrusion Line – JWELL Detail:

Production line features

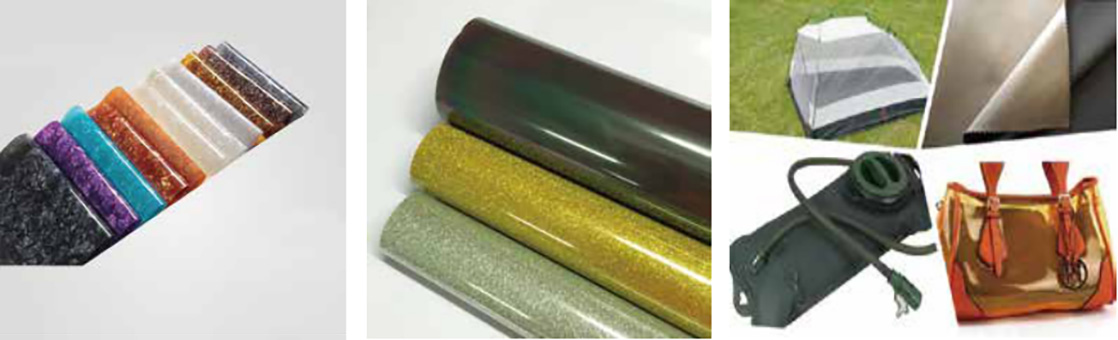

TPU raw materials with different temperature and hardness ranges are extruded by two or three extruders at one time. Compared with the traditional composite process, it is more economical, more environmentally friendly and more efficient to recombine high-temperature and low-temperature thin films offline.

Main technical specification

|

Model |

Products width |

Products thickness |

Capacity |

|

JWS90+JWS100 |

1000-2000mm |

0.02-0.5mm |

200-250kg/h |

|

JWS90+JWS90+JWS90 |

1000-2000mm |

0.02-0.5mm |

200-300kg/h |

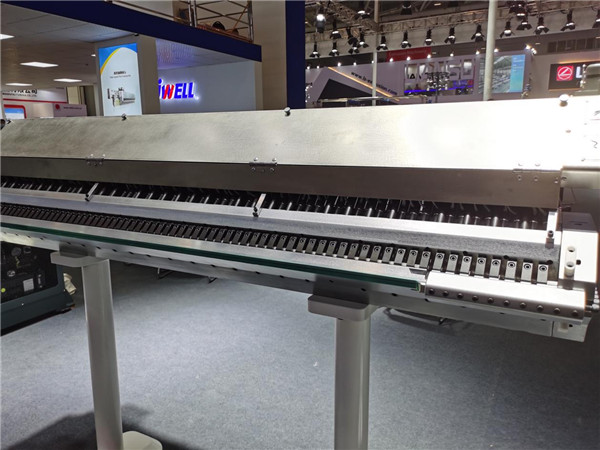

The die (mold) adopts an extension V shape water-drop type flow channel,with the shunt technology and special triangle stabilize structure. To composite layer and improve the precision of the extrusion process to eliminate ‘M’ shape and ‘W’ shape flow patterns effectively. The upper die lip using push-off type manual fine-tuning + automatic fine-tuning one-piece die lip, manual adjustment range is ±1mm, automatic adjustment range±300um; About the automatic die lip adjustment control parts ,we use currently very advanced fully closed loop control system and the automatic gauging system makes the product thickness in±2% precisely, on-line thickness gauge is automatic continuous detecting scanning frequently, can shows the very real-time accurate thickness tolerance of the products. Through computer program processing the data, feedback to special die lip adjusting bolt thermal expansion, and to realize the opening of the die lip thickness for automatic fine-tuning, fast and effective control product thickness precisely. And we have good die head scalability, according to customers’needs , matching with different “inside blocking type width adjusting device” or “the outer blocking type width adjusting device”, be better satisfied customer’s needs to more efficient production.

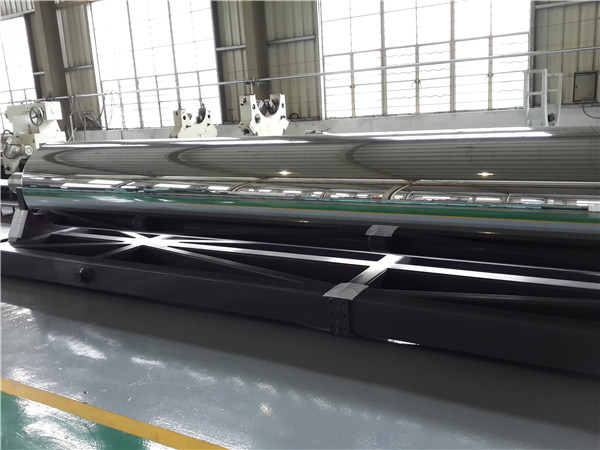

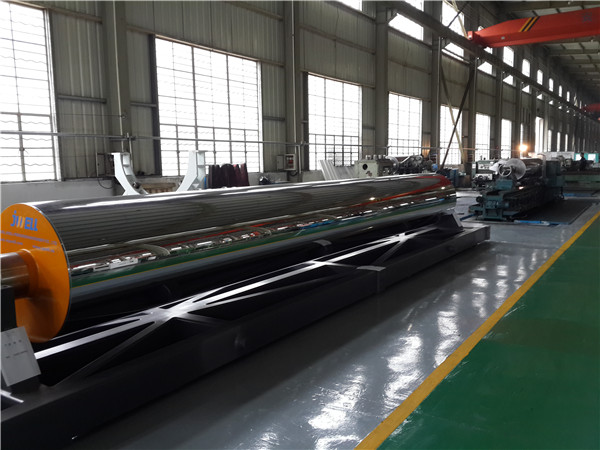

Super Mirror Roller

● The surface roughness level of the roller can be reached Ra0.005-0.01μm;

● The cylindricity and cocentricity of the roller can be reached ≤0.005mm;

● Enhanced roller rigidity and minimized roller surface temperature deviation through special roller structure design.

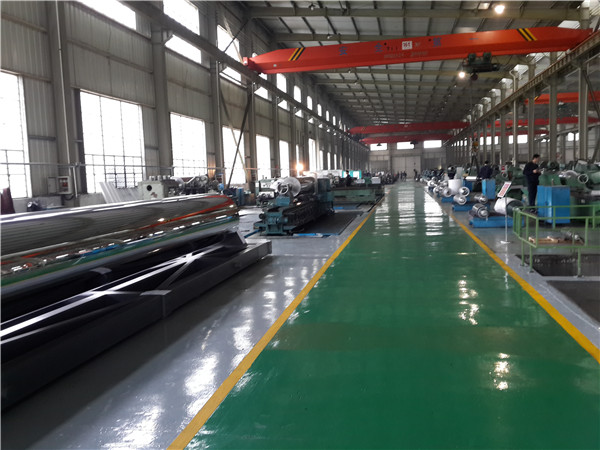

Product detail pictures:

Related Product Guide:

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for TPU High-low Temperature/High-elastic Film Co-extrusion Line – JWELL , The product will supply to all over the world, such as: Vancouver, Orlando, Serbia, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.