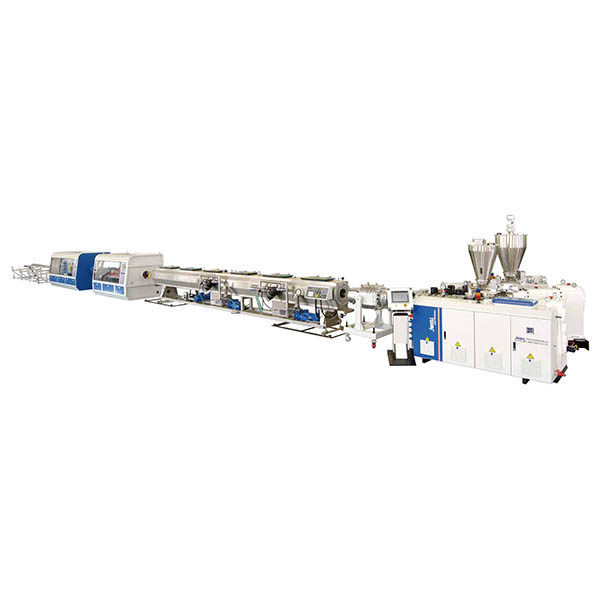

Three-layer PVC Solid Wall Pipe Co-extrusion Machine

Performance&Advantages

Use two or more SJZ series conical twin screw extruder to implement co-extruded three-layer PVC pipe. The sandwich layer of the pipe is high-calcium PVC or PVC foam raw material.

1. The extruder uses super wear-resistant alloy screw barrel; the twin-screw feeds evenly and the powder doesn't bridge;

2. Optimized design of PVC three-layer mold, the internal flow channel is chrome-plated and highly polished, wear and corrosion resistant; with special sizing sleeve, the pipe product has high speed and good surface;

3. Cutting machine adopts rotating clamping device to adapt to different pipe diameters, eliminating the trouble of frequent replacement of fixtures. Equipped with a new type of adjustable floating chamfering mechanism, the size of chamfer can be adjusted according to the pipe diameter and wall thickness, cutting and chamfering can be performed in one step. Closed suction device, better chip suction effect.

Planetary Saw Cutting Machine Performance & Advantages

The equipment running stably and reliably, adopt high-speed rotating saw, Circular Saw blade cut the pipe. Suitable for extra thick large - diameter pipe; Cemented carbide cutting blades, high wear resistance and long service life; Powerful suction chips Dust removal used ionic wind, equipped with dust filters collection device.

In view of the large diameter PVC pipe is equipped with a dedicated chamfering cutter, tungsten carbide blade, sharp and durable; The internal structure of advanced design, make the PVC pipe cutter surface smooth and tidy, chamfer Angle and uniformity nice.

For small diameter PVC pipe, we had a special high-speed cutting machine dust - free. Ribbon cuttings avoid the pollution of dust on the work shop.

Main technical specification

|

Model |

Pipe diameter |

Extruder |

Main Power |

Capacity |

|

JWG-PVC250 |

Φ75-250mm |

SJZ65/132+55/110 |

37+22kw |

300~400kg/h |

|

JWG-PVC450 |

Φ200-450mm |

SJZ80/156+65/132 |

55+37kw |

400~600kg/h |

|

JWG-PVC630 |

Φ315-630mm |

SJZ92/188+65/132 |

110+37kw |

740~900kg/h |

Product image display

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.