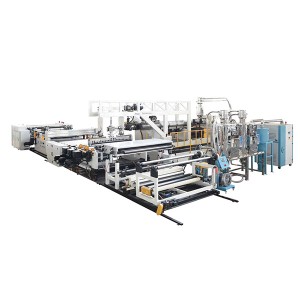

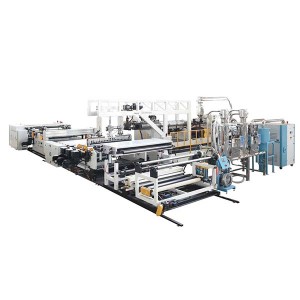

Stretch Film Extrusion Line

Product description

The equipment is composed by extruder, die head, sheet cast, lognitudinal stretch, transverse stretching, automatic winder and controlling system. Relying on our advanced designing and processing ability, our equipment's features are:

● Special designed lognitudinal strech roller.

● Driving and controlling system are from world famous brand.

● Controlling system is from precision PLC program.

● High stretch acuracy, high speed, and steady working status.

We are able to design equipment as per customer's request with high acuracy stretch equipment: 1-10 streching ratio, width range will be 500-3000mm, thickness range will be 0.05-0.3mm.

Casting film is a kind of film produced by melt casting quenching. There are two ways: single-layer casting and multi-layer coextrusion casting. Compared with film blowing, it is characterized by fast production speed, high output, and excellent transparency, gloss and thickness uniformity of the film.

Tape casting film has excellent heat sealing performance and excellent transparency. It is one of the main packaging composite substrates. It is used to produce high-temperature cooking film and vacuum aluminizing film. The market is very promising. Moreover, with the development of domestic casting film production equipment, some technical indexes have reached the international advanced level.

1). The domestic casting film production line can be divided into 2500mm, 3000mm, 3500mm and 5000mm according to the film width, and can be divided into three layers, five layers and seven layers according to the configuration of extruder.

2). The casting film production line is mainly composed of extrusion part, casting part, corona part, winding part and electric control part. The mold part and extrusion part can be combined freely according to the requirements of customers, so as to meet the different needs of customers (market) to the greatest extent.

3). In addition, the design of domestic equipment also follows the international advanced level, such as:

A. The unique design of extrusion device can freely adjust the pressure of extruder.

B. The unique design of screw runner can be applied to different materials to realize multi-purpose of one machine.

C. The flow channel design of the roller has better cooling effect, more stable product quality and higher output.

D. The line speed of domestic casting film production line has reached the level of 160m / min-350m / min.

4). Compared with imported equipment, domestic casting film production line also has the characteristics of high speed, stable performance, environmental protection and energy saving.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.