PP Hollow Building Formwork Extrusion Line

PP Hollow Building Formwork is an energy-saving and green environmental protection product. It is another new generation product after wood formwork, combined steel formwork, bamboo wood glued formwork and all steel large formwork. It can completely replace the traditional steel formwork and wood formwork, with energy conservation, environmental protection and low amortization cost.

Eight advantages

1. Smooth and smooth. The formwork shall be spliced tightly and smoothly. After demoulding, the surface and finish of the concrete structure shall exceed the technical requirements of the existing fair faced formwork. There is no need for secondary plastering, which saves labor and materials.

2. Light and easy to wear. With light weight and strong process adaptability, it can be sawed, planed, drilled and nailed, and can form any geometry at will to meet the needs of building formwork of various shapes.

3. Easy demoulding. The concrete does not stick to the slab surface and does not need release agent. It is easy to demould and remove ash.

4. Stable and weather resistant. High mechanical strength, no swelling, cracking, deformation, stable size, alkali resistance, anti-corrosion, flame retardant and waterproof, rat and insect repellent under the temperature of - 20 ℃ to + 60 ℃.

5. Conducive to maintenance. The formwork does not absorb water and does not need special maintenance or storage.

6. Strong variability. The type, shape and specification can be customized according to the requirements of construction engineering.

7. Reduce costs. The turnover times are many, the plane formwork is no less than 30 times, and the column beam formwork is no less than 40 times, with low use cost.

8. Energy saving and environmental protection. All leftover materials and waste formwork can be recycled.

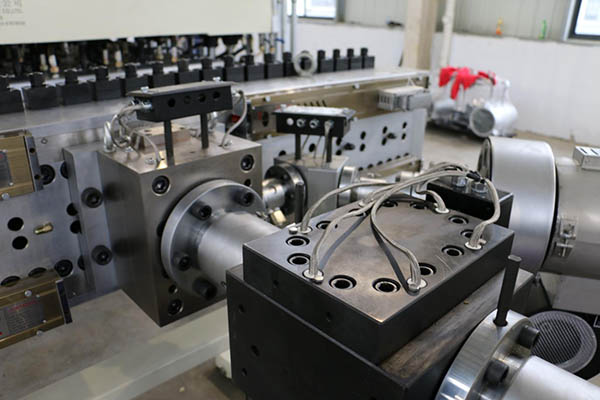

JWELL produced PP one mold double out building template production line on the basis of the traditional 915mm single production line,that not only could meet the demand of large output and low energy.

Characteristics

1. Three layer coextrusion production line

2. Three layer composite distributor

3. Multi-layer lattice mold

4. Three grade type board

5. Combined tractor

6. Automatic fixed length cutting machine

Main technical specification

|

Model |

Material |

Extruder specification |

Products width(mm) |

thickness(mm) |

Capacity(kg/h) |

|

JWS130(80)-1320 |

PP modified material |

JWS130/35, JWS80/35 |

915/1220 |

12-14/15-17 |

450-500 |

|

JWS150(80)-2000 |

PP modified material |

JWS150/35, JWS80/35 |

915*2 |

12-14/15-17 |

550-600 |

|

CJWH85(80/52)-2000 |

PP modified material |

CJWH85, CJWH52/JWS80 |

915*2 |

12-14/15-17 |

600-700 |

Note: The specifications are subject to change without prior notice.

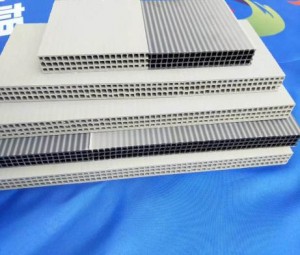

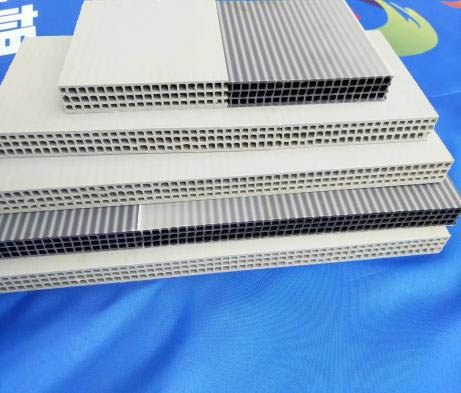

Product image display

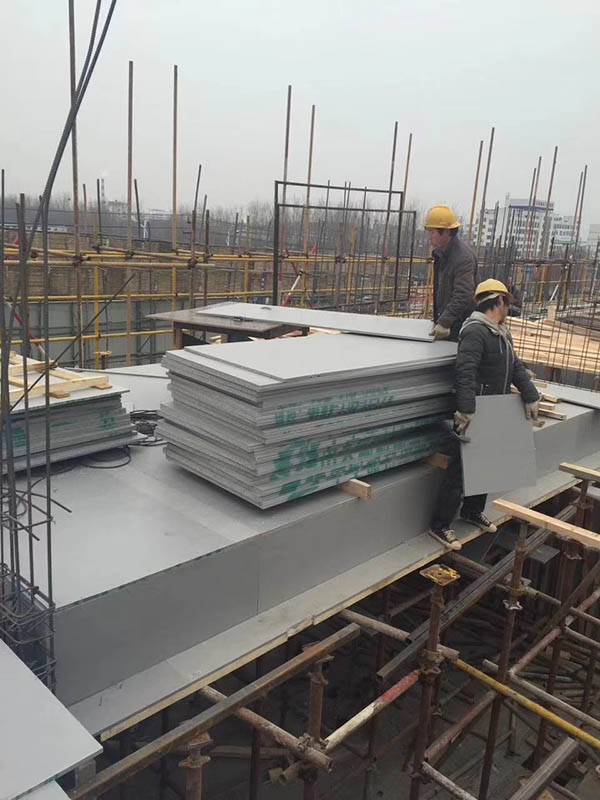

Construction site

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.