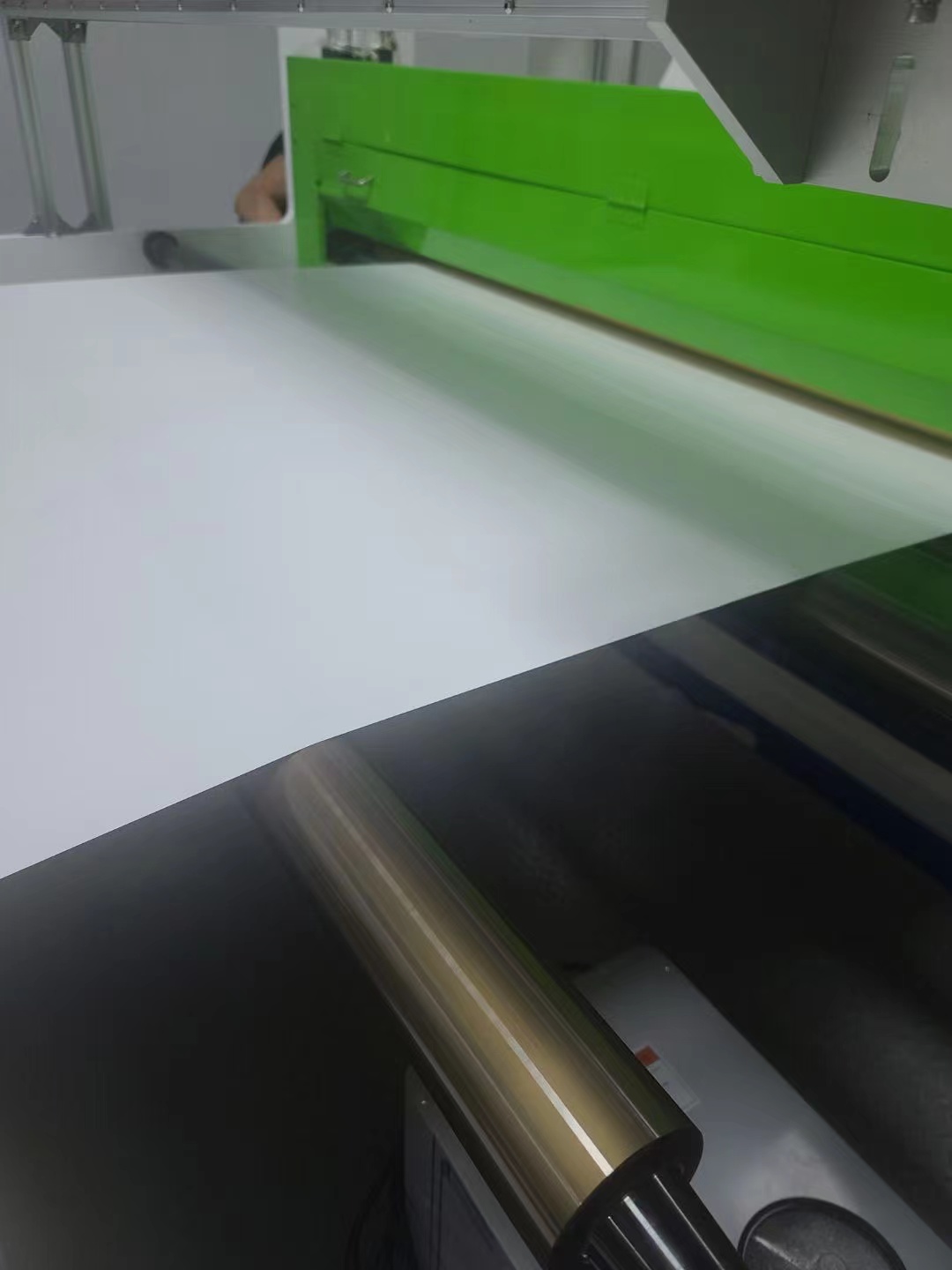

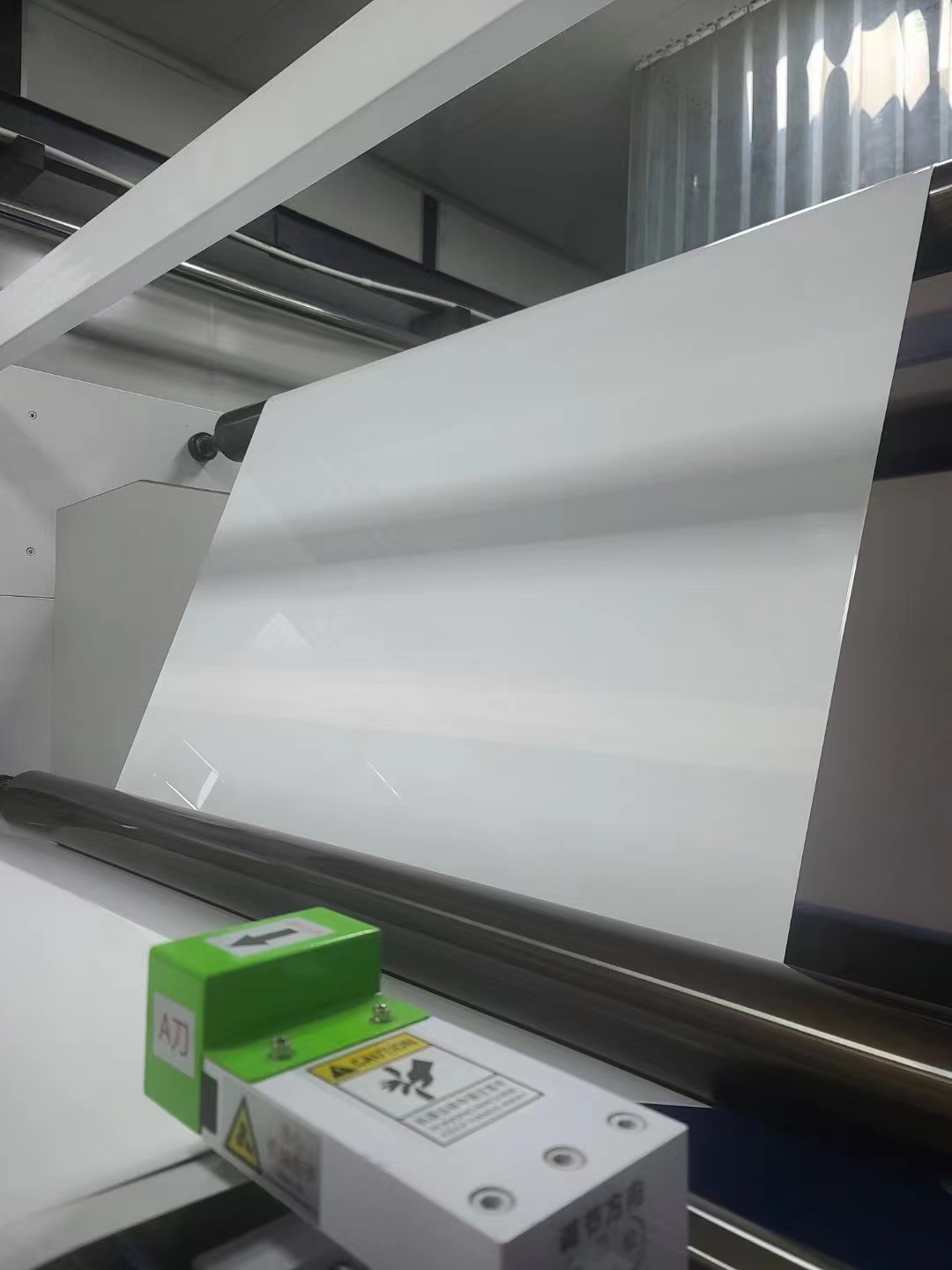

PETG decorative film production line

The advantages of PETG decorative film, high gloss film, skin sensitive film and other decorative applications are as follows:

1. Weather resistance: PETG plate provides excellent weather resistance. It can maintain the toughness of the product and prevent yellowing. It contains ultraviolet absorbent, which can be extruded into a protective layer to protect the plate from the harmful effects of ultraviolet rays.

2. Simple processing: PETG plates can be sawed, die cut, drilled, punched, sheared, riveted, milled and cold bent without breaking. Slight scratches on the surface can be eliminated by hot air. Solvent bonding is also a routine operation. It is easier to process than general acrylic, impact modified acrylic or PC board, and can be processed by flocking, electroplating, static electricity, etc.

3. Excellent chemical resistance: PETG plate can withstand a variety of chemicals and commonly used detergents.

4. Environmental protection: PETG plate base materials are environmental protection materials, which meet the requirements of food contact management.

5. Safety: antibacterial and mildew proof.

Advantages of the equipment of the PETG high gloss film production line of Jwell machinery:

Advantages of the equipment of the PETG high gloss film production line of Jwell machinery:

1. It can be configured according to customer needs, and is highly customized to meet different customer needs.

2. J type or 45 ° three rollers can be selected according to the operation habits:

3. Single layer PETG decorative sheets can be produced by a single machine, or gag (petg+apet+petg) decorative sheets can be produced by a coextrusion machine to save costs.

4. The reduction box is made of steel castings, the gear is made of alloy steel and grinded, the lubrication points in the box are forced lubrication, and the lubricating oil is equipped with a water cooling system.

5. The screw barrel is made of alloy nitrided steel, which is nitrided and sprayed with alloy on the surface.

6. The roller adopts alloy steel thin-wall roller and special internal spiral channel to meet the requirements of high production for roller cooling speed.

7. Each extrusion host is linked with the main control touch screen, which can be operated and monitored remotely.

8. High precision melt pump can improve the plasticization and homogenization effect of materials and accurate measurement, so as to improve product quality.

9. The waste edge collection device facilitates the collection of cutting waste and improves the winding quality.

10. The constant tension winding device can improve the tidiness and beauty of winding.

11. Different surface treatments of products can be achieved by selecting tread rollers / fog rollers, etc.

Q1: I don’t know which one is suitable for me?

A:Please tell me

1)Your materials(For example: PP,PE, PS, ABS, PET, PC etc.)

2)What field (or industry) are your products used in?

3)The width(mm)of your product.

4)The thickness(mm)of your product.

5)The output(kg/h)you need.

Q2:How long is the delivery date?

A:The normal delivery time of the production line is 3-4 months, and that of special customization is 4-6 months.

Q3:What is the payment terms?

A:T/T,L/C,Cash and so on.

Q4:How about warranty?

A:In condition that Buyer follows regulations of product preservation and usage, the Seller agree to warranty of 12 months from the date of equipment installation, or 18 months after delivery, whichever comes first.

Q5:Do you have CE document and other document for customs clearance?

A:Yes,we have original.At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/sales contract for customs clearance.

Q6:I don’t know how to use after I receive or I have problem during use,how to do?

A:1)After the goods arrive at your factory, contact us to arrange engineers to serve in your factory.Commissioning service includes supervision of installation and start-up, on-site training. The Buyer should offer the transportation, accommodation and food for the engineer(s) of the Seller within the territory of the Buyer’s country. Service charges are free.

2)If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/WhatsApp/WeChat/Email/Phone with cam till all of your problems finished.We can also provide Door service if you need.