The COVID-19 is raging. How can rubber and plastic equipment manufactures meet the needs of epidemic prevention and control to ensure supply demand? Mr. Wang Liang, the general manager of Shanghai Jwell Extrusion Machinery Co., Ltd. accepted the theme visit of "CPRJ" /AdsaleCPRJ.com on the topic of epidemic prevention and introduced how the company can grasp the epidemic prevention Control, and work with everyone to fight the epidemic; grasp production in one hand, ensure market supply, and meet customer needs.

Mr.Wangliang ---The General Manager of Shanghai Jwell Extrusion Machinery Co.,Ltd

24 hours online technical support

Mr.Wang said that in order to alleviate the shortage of epidemic prevention materials as soon as possible, many customers of Jwell Machinery in the rubber and plastics industry gave up the CNY holiday and worked overtime to make the epidemic prevention materials reach the front line of epidemic prevention faster.

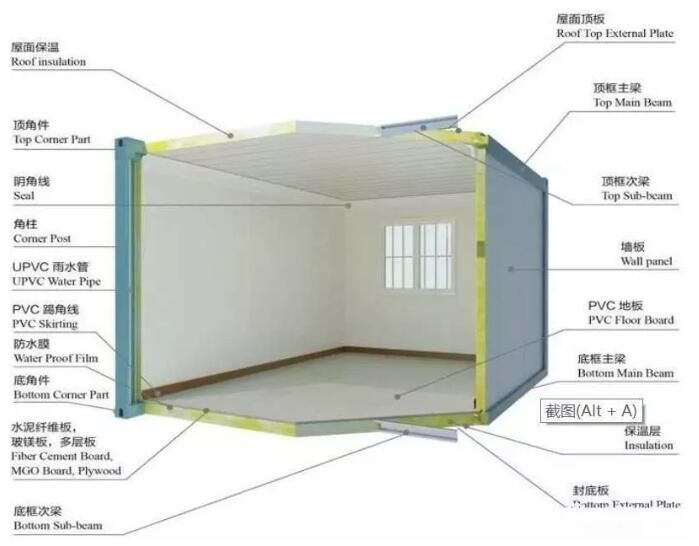

Jwell Machinery, as a supplier of equipment, also actively cooperates with the production and supply of anti-epidemic materials. "In January 2020, when we learned that many customers were working overtime for various types of new plastic building materials (waterproof coils, municipal engineering pipes, integrated assembly environmental protection building materials) for the construction of Leishenshan and Huoshenshan hospital, we immediately decided to give up the CNY. During the holidays, move quickly, mobilize elite soldiers, equipment maintenance engineers, and provide on-site linkage with customers through remote terminal guidance to provide stable start-up production for users of the company and provide 24-hour technical support services. "Mr. Wang said.

Jwell Machinery Overall Solution of Smart Factory

Return to work in advance Supply of non-woven fabric / film extruder

With the rapid development of the epidemic, supplies of anti-epidemic materials such as masks, protective clothing, and non-woven fabrics for the production of masks have become urgent. In order to ensure the production capacity of mask raw materials and protective clothing raw materials, Jwell quickly organized employees under the supervision of all parties, and on the premise of doing its own epidemic prevention and control, obtained the permit to resume work on February 4. .

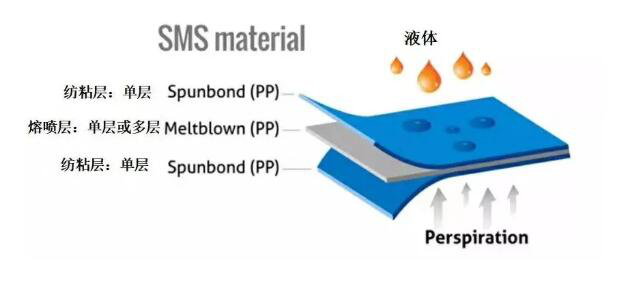

Jwell Machinery actively provides professional extrusion machinery and equipment support for the protection industry: PP non-woven extruder / PP meltblown non-woven extruder / TPU / EVA / TPE film extrusion line.

Schematic diagram of SMS non-woven fabric.

Mr.Wang told reporters that at present, the market demand for sanitary and anti-epidemic materials is very hot, and several popular products are in short supply. After the company resumes work, there are more orders and it is very popular in the market.

PP Non-woven /PP Meltblown non-woven fabric extrusion machinery

Jwell has extensive experience in the medical materials industry. Among them, polypropylene meltblown nonwovens, which are important materials for epidemic prevention and control, use special polypropylene raw materials and add trace medical grade additives,Medical materials made of special materials produced by Jwell parallel twin screw extrusion process using unique process technology. This special material has the characteristics of stable fluidity, narrow molecular weight distribution, and excellent spinning performance. It is used to produce meltblown non-woven materials and can be widely used in medical protection, sanitary materials, filter materials and other fields.

This solution provides a complete set of solutions for many professional manufacturers in China and abroad. Jwell is coordinating the supply chain and is preparing to provide more production lines for domestic related enterprises to contribute more to epidemic prevention.

TPU / EVA / TPE film extrusion line

TPU film is based on TPU pellets and made into a film through a casting process. Jwell draws on the production experience of many polyurethane TPU manufacturers. Through optimization and innovation, it uses one or more single-screw extruders for coextrusion. Each extruder is divided into 8 temperature control zones for precise temperature control and maximum output It can reach 600KG / H, and it can be used in single-layer, A / B / A or A / B distribution mode. TPU film has excellent characteristics such as environmental protection, non-toxic, anti-mildew, anti-bacterial, wear-resistant and anti-corrosion, and bio-compatible. Widely used in medical isolation clothing, protective hats and other medical isolation products of health and epidemic prevention materials and shoes, clothing, inflatable toys, sports equipment, medical equipment, fitness equipment, etc.

Based on the requirements of factory digitalization and intelligent management, this series of models provide functions such as automatic control, data acquisition, data storage, data analysis, production management, global remote synchronous monitoring, etc., to realize the entire set of extruder production lines or extruder factory management and Digitalization and visualization of processes. Very cost-effective.

Mr.Wang said that at present, most of the staff in the workshop assembly and machining have arrived. Due to the company's prevention and control work in place, although the epidemic has hindered the resumption of mass production, it can still guarantee the normal production and operation of the factory. First batch equipment in the year of Mice was loaded and shipped to Germany today.

"This kind of belief has become the consensus of Jwellist." As long as we fight hard and pay attention to safety and efficiency, the order in hand will definitely be delivered when pressed. "Jwell Company is coordinating the supply chain and preparing to provide more production lines for domestic and foreign related enterprises to contribute to epidemic prevention and epidemic prevention.

Post time: Jan-01-2020